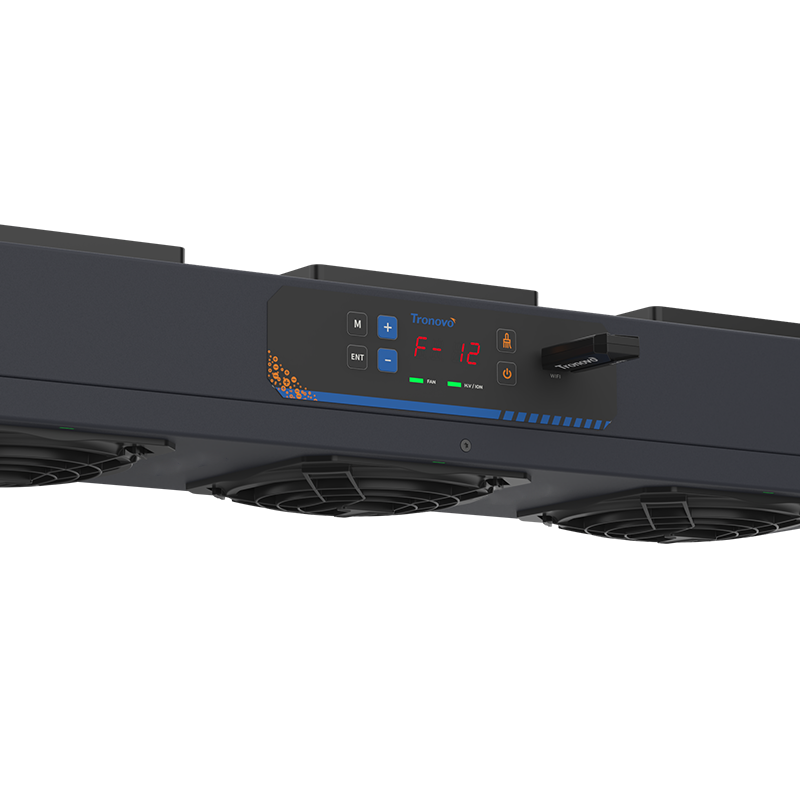

DF46X-A Smart HF Ionizing Air Blower

0

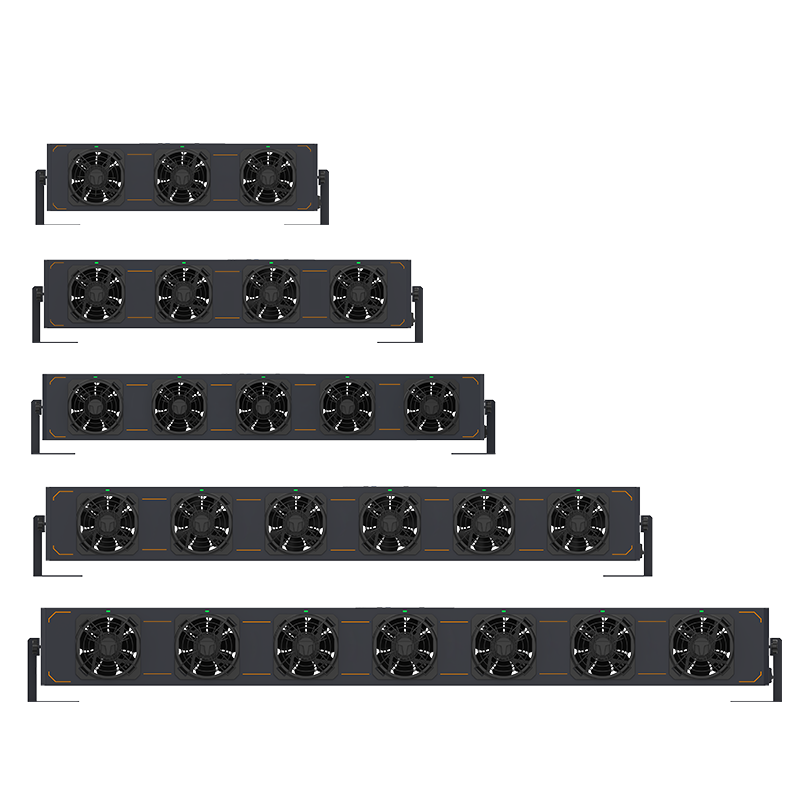

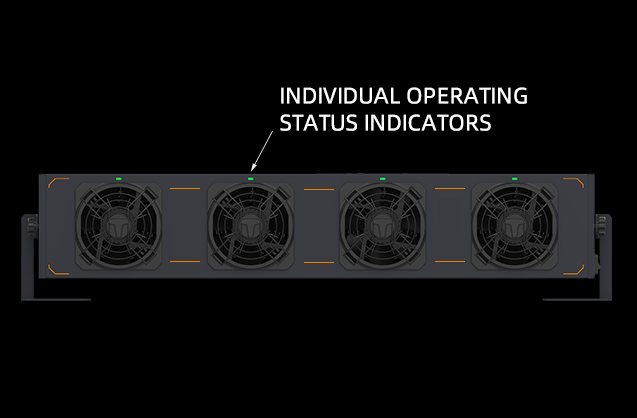

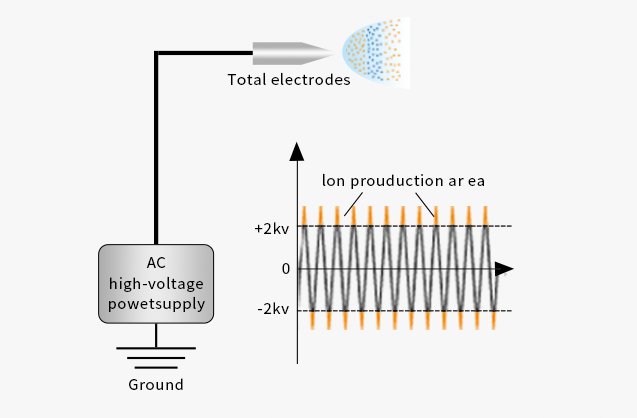

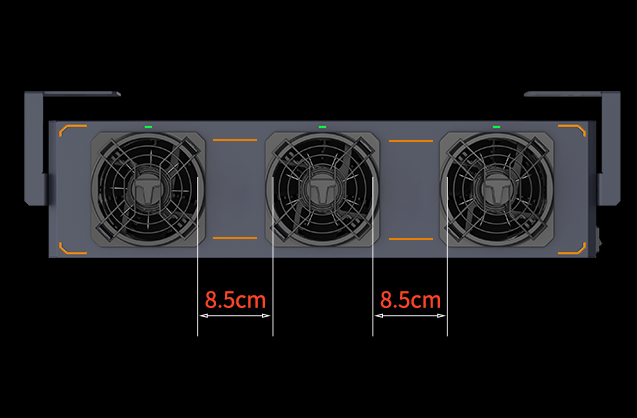

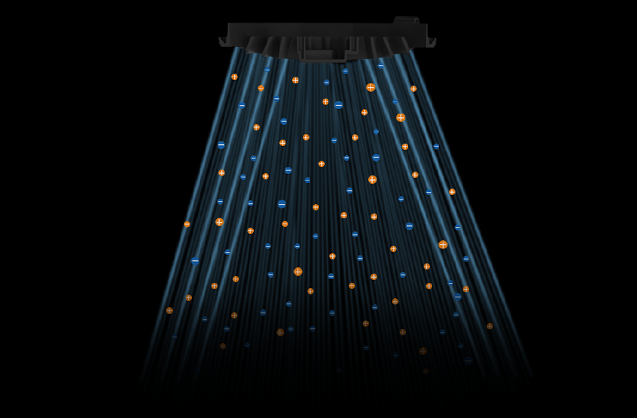

Specially designed for electronic manufacturing and assembly of high-frequency ionization ion fan, equipped with high-speed fan and high-frequency AC technology, to achieve high-speed static elimination, efficiency increased by 30%. Reliable line design, built-in ion needle cleaning brush, automatic maintenance to reduce manual intervention, significantly reduce the frequency of maintenance. Equipped with five self-alarm monitoring functions, each air outlet is equipped with a status indicator, real-time display of operating status, to ensure production safety.