You may also be interested in these products

Product Parameter

- Model

- DF241

- Voltage

- 24VDC±5%

- Power

- 16W

- Discharge

- ≤1.5S @ 30cm (Max Airflow)

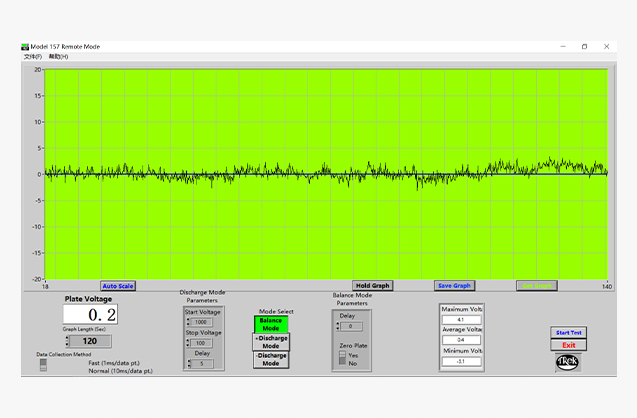

- Balance

- ≤|±10V|(AVE)

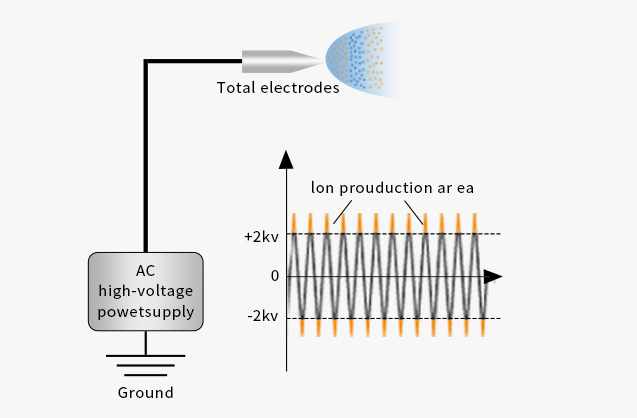

- Technology

- High-frequency Ac mode, about +2kV, 70KHz

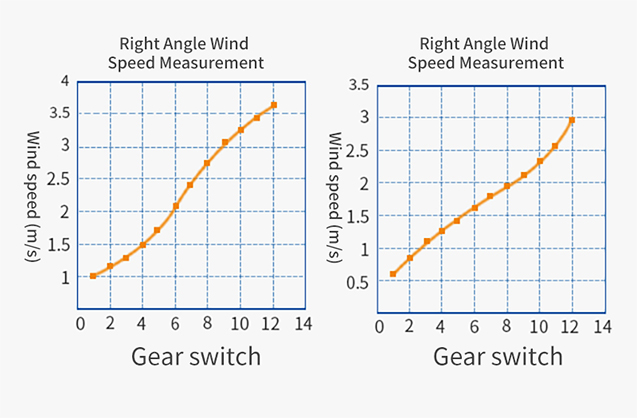

- Airflow

- 10~120CFM

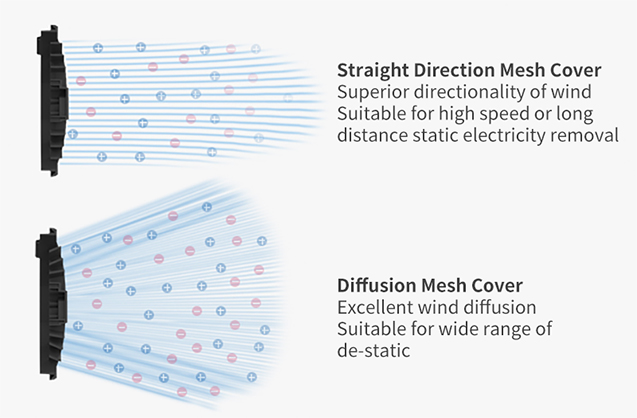

- Airflow area

- 20x150cm (Angle),40x120cm (Straight)

- Audible Noise

- 45~75dBA @ 100cm (min~max airflow)

- Ozone

- ≤0.04ppm @ 15cm

- Alarm

- Case & H.V

- Interface

- ✘

- Material

- Discharge needle: tungsten, shell: metal, grille: ABS

- Temperature

- 0~+45℃ (note no condensation),35~75%RH

- Dimensions

- 200x180x85mm (including stand) /Approx. 1.3Kg

- Warranty

- One-year