DF261 Cleaning Ionizing Air Blower

0

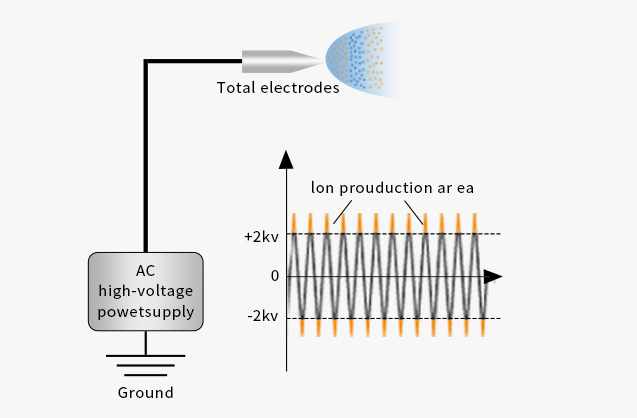

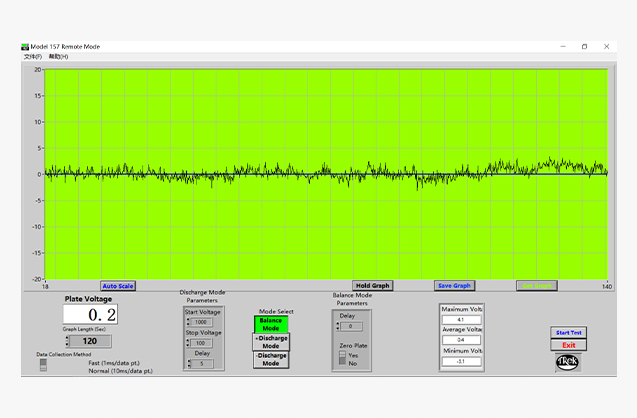

Adopting 70,000Hz high-frequency AC technology, the static eliminator achieves efficient synergistic release of positive and negative ions through high-frequency AC electric field, which significantly improves the speed and stability of static electricity neutralisation. Compared with traditional low-frequency or DC methods, high-frequency AC technology can maintain an ultra-low ionic balance offset of ±10V under high ion concentration environments, and can cover a wider range of static elimination without frequent adjustment of installation distance.