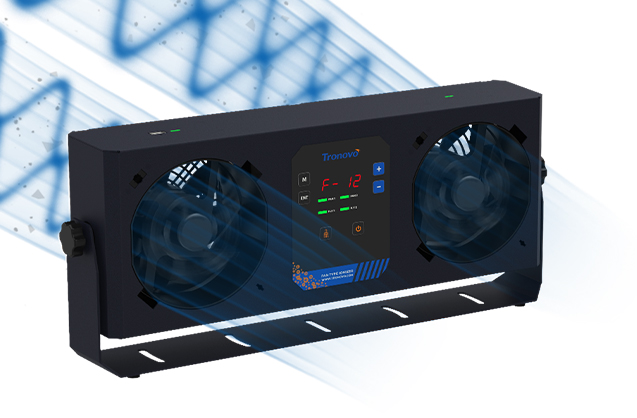

DF462 Smart HF Ionizing Air Blower

0

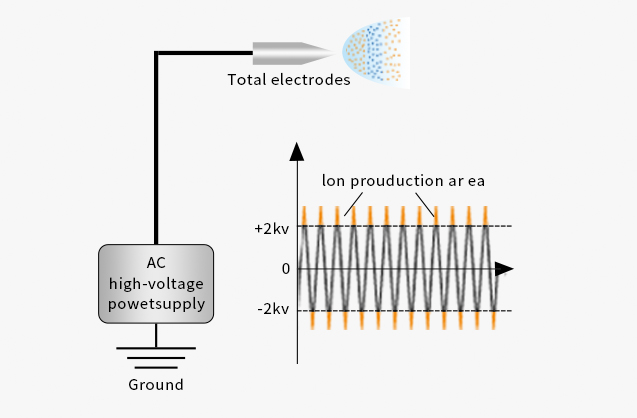

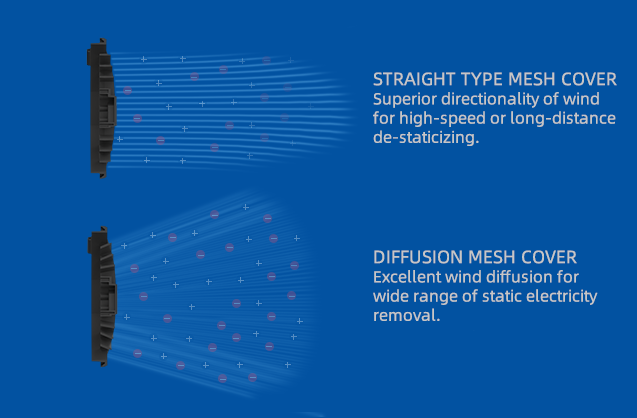

Using 70,000Hz high frequency ionization technology, the ion balance is stable at ± 10V, and the static electricity is effectively neutralized within 1.5 seconds. Equipped with high air volume fan, covering 600mm range, suitable for electronic manufacturing, medical and other precision industries. Equipped with intelligent maintenance: exclusive appointment cleaning function, automatic cleaning of ion needles, reducing manual maintenance costs by 90%. Safe and controllable: Six-fold self-inspection alarm system, each air outlet is equipped with a status indicator to monitor the running status in real time.