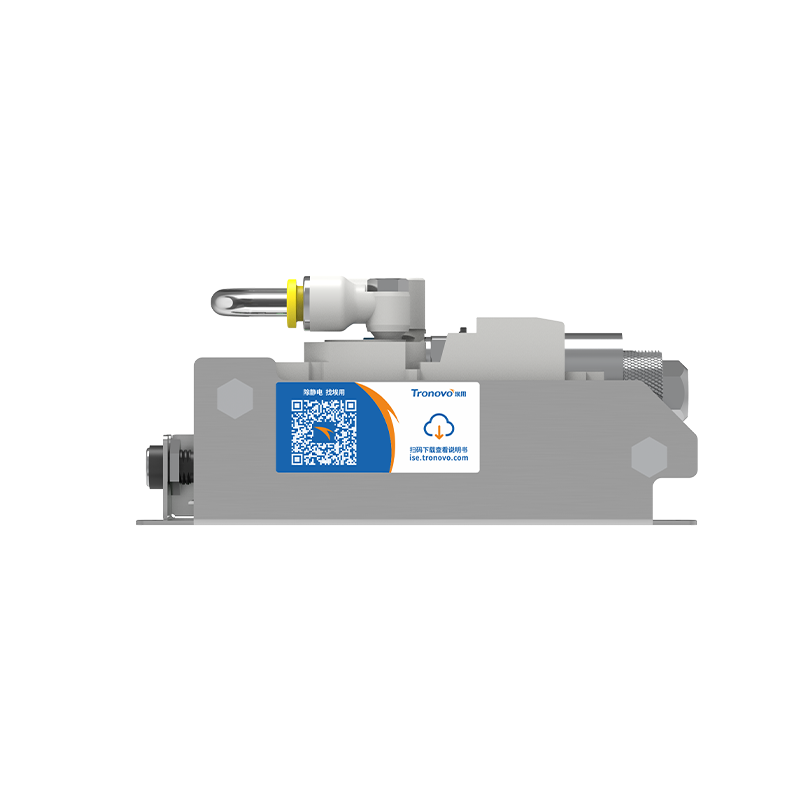

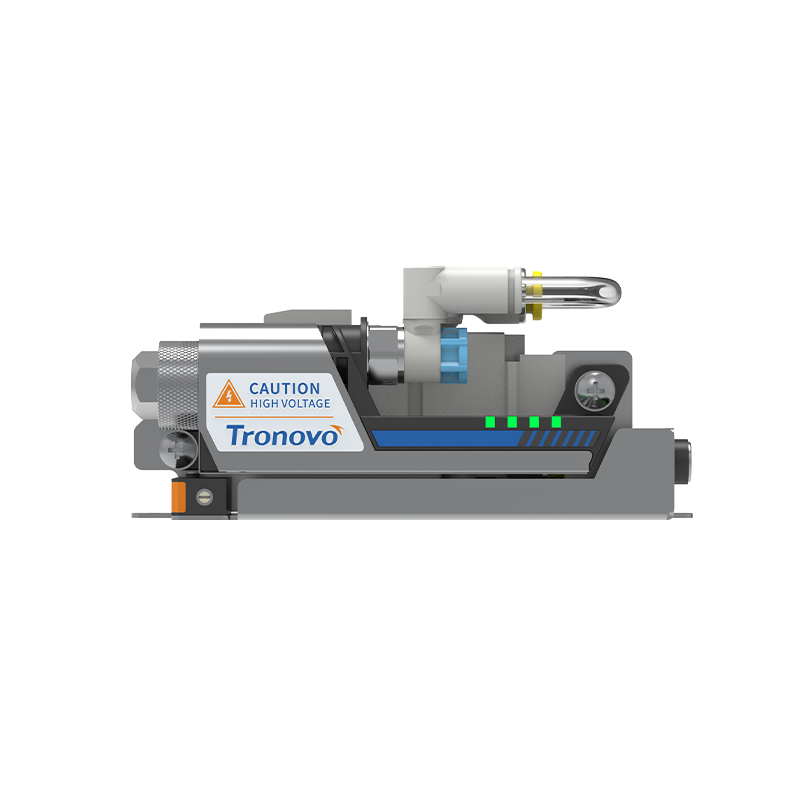

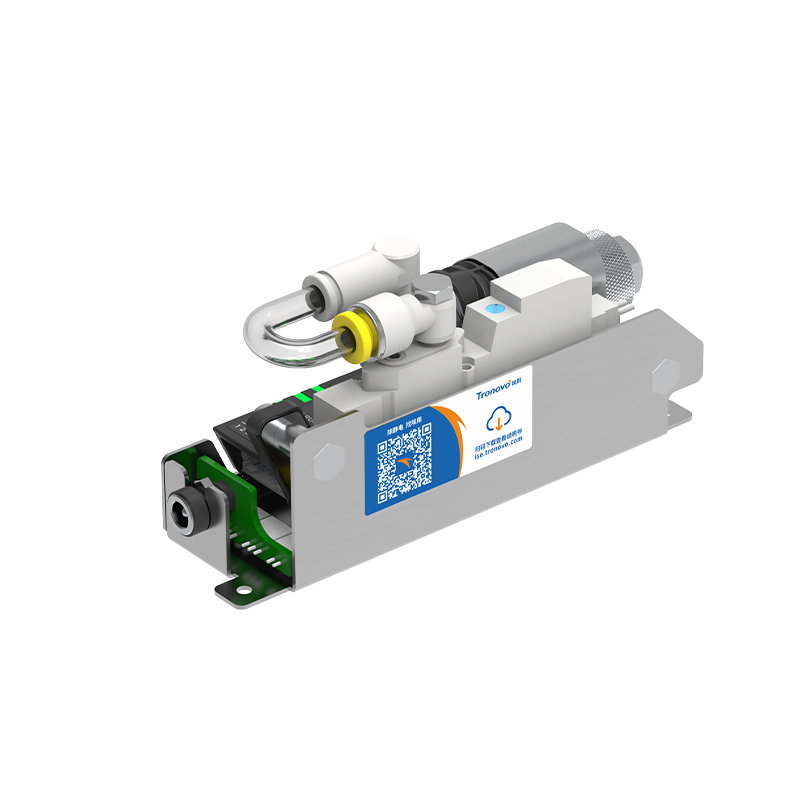

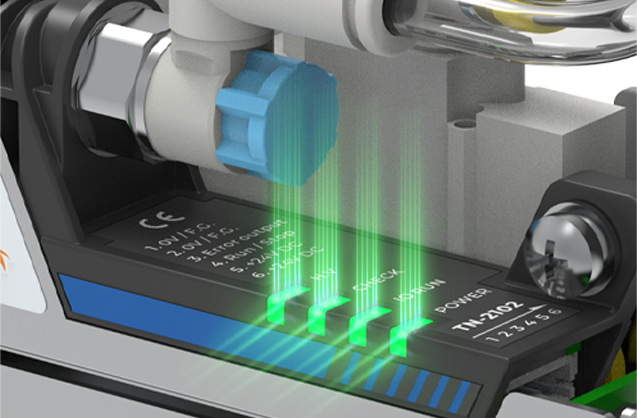

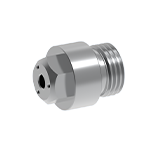

DN253 Gas-electric Control Hf Ionizing Nozzle

0

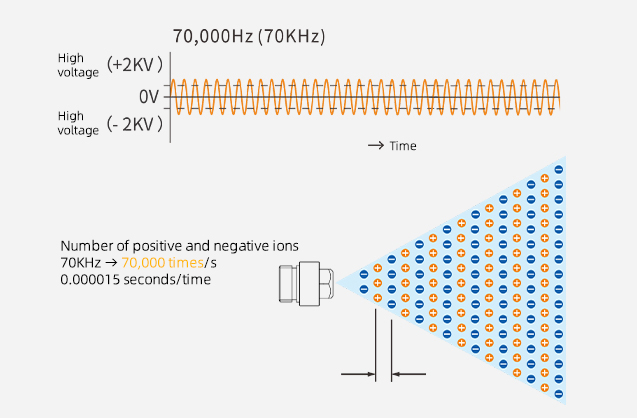

In Charge neutralization is important for removing particles from the surface, which can be difficult to remove once they are adsorbed on the charged surface of the material. Inductive ionizing nozzles based on high-frequency AC technology, miniaturized design, suitable for automated processes and cleaning applications with general space constraints. This model is equipped with a proximity sensor, and when the object is close to the sensing surface to the operating distance, the strong ionized air force can effectively remove the object attracted by the particles.