|

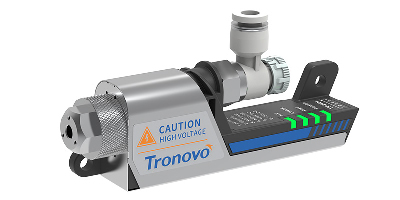

MODEL NUMBER

|

Body style

|

Nozzle Accessories

|

Material

|

ILLUSTRATE

|

|

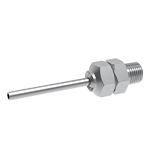

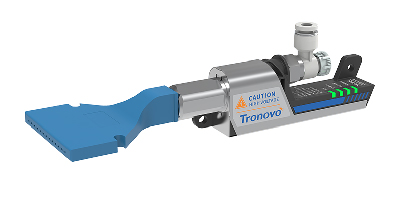

Diffusion nozzles

|

MODEL:DN251-SN01

|

MODEL:TN-SN01

|

SUS 304

|

Straight lines diffuse the air

|

|

Shower-type nozzles

|

MODEL:DN251-SN02

|

MODEL:TN-SN02

|

SUS 304

|

45 degree spray angle for wider air diffusion

|

|

Connected hose nozzles

|

MODEL:DN251-SN03

|

MODEL:TN-SN03

|

Metal

|

Ion nozzle body and conduit connection nozzle can be connected to any bend of the conductive conduit conduit diameter ø 6mm, the minimum bending radius: R25mm, need to purchase additional TN-SN10 adapter to use.

|

|

Adjustable point nozzle

|

MODEL:DN251-SN04

|

MODEL:TN-SN04

|

SUS 304

|

Can be in the range of 60 degrees, arbitrary adjustment of the spray angle to use first adjust the nozzle after the fixed nut, need to purchase additional TN-SN10 adapter to use!

|

|

Round-nosed nozzles

|

MODEL:DN251-SN05

|

MODEL:TN-SN05

|

Plastics

|

Powerful straight-line air can be injected from a small hole at the front end, with the addition of the TN-SN10 adapter.

|

|

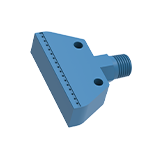

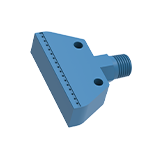

Flat-head nozzles

|

MODEL:DN251-SN06

|

MODEL:TN-SN06

|

Plastics

|

Wide range of uniform electrostatic dust removal, requires additional TN-SN10 adapter for use

|

|

90-degree nozzle

|

MODEL:DN251-SN07

|

MODEL:TN-SN07

|

Plastics

|

The angle of the air jet is perpendicular to the threaded surface, making it ideal for space-constrained locations,Requires additional TN-SN10 adapter to use

|

|

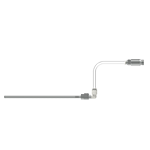

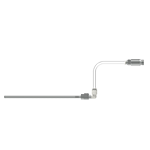

Stick type side blow nozzle

|

MODEL:DN251-SN08

|

MODEL:TN-SN08

|

SUS 304

|

De-static effective length 270mm can improve the de-static area suitable for space-restricted places, need to add the purchase of TN-SN10 adapter use

|

|

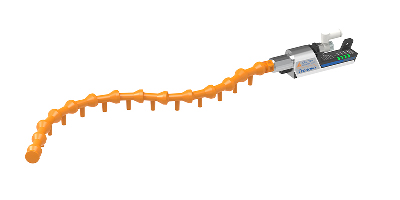

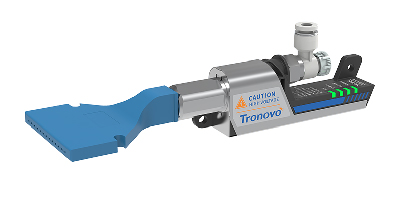

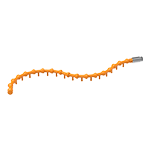

Rod type side blow nozzle + bendable hose

|

MODEL:DN251-SN09

|

MODEL:TN-SN09

|

SUS 304

|

De-static effective length of 270mm, the rod-type side blowing nozzle edge to the conductive conduit conduit diameter ø 6mm, the minimum bending radius: R25mm, the length of the conduit has a greater impact on the time to remove static electricity, please follow the site to do the choice of the appropriate, need to add the purchase of the TN-SN10 adapter to use!

|

|

Nozzle adapters

|

|

MODEL:TN-SN10

|

SUS 304

|

RP1/4 (female) to M16×1.5 (male) is suitable between the nozzle and the thread of the static eliminator.

|

|

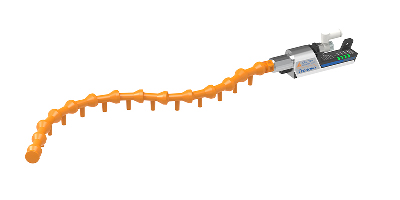

Bamboo gimbal nozzle

|

MODEL:DN251-SN19

|

MODEL:TN-SN19

|

Shuo material

|

It can be installed on DN251 or DN252, the default length of the product is 40cm, and there are 13 nozzles in total.

Customers can shorten or extend as needed.

|

|

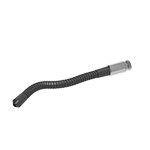

Universal nozzle

|

MODEL:DN251-SN20

|

MODEL:TN-SN20

|

Metal

|

The nozzle can be bent arbitrarily and does not need to be fixed

Keep the curved shape unchanged, using a flower wine nozzle

Can increase the elimination area

|

|

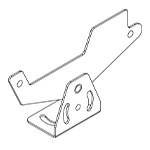

Rotate the fixing bracket

|

|

MODEL:TN-RB01

|

SUS 304

|

The ionic nozzle body is fixed and installed

|