MR63RS Dedicated Factory Audits Test Kit

Designed for anti-static engineering

Added Extension Rod Kit

No need to bend over to move electrode

|

New TFT large screen displaysDisplays resistance tail and index, temperature, relative temperature, and analogue pointer display function. Since humidity and temperature affect the electrical properties of the material being tested. Low temperature and humidity will increase the resistance value and slow down the dissipation time. Under high humidity conditions, a thin layer of water will condense on the surface of the object to be tested or be absorbed by it, and this hygroscopicity increases the electrical conductivity of the material, and this is especially true for materials that are highly water-absorbent. |

MR63 Digital Surface Volume Resistivity MeterThe MR63 is a comprehensive anti-static measuring instrument for checking surface and ground resistance, measuring the impedance or resistance of all conductive, antistatic, and electrostatic venting surfaces, as well as the relative humidity and temperature that affect electrical properties. |

|

|

New data logging and exporting - in a flash drive!Store and recall up to 99 measurements and support connection to a PC for exporting test data. |

TM-HHE Handheld Electrode AssembliesHandle for measuring human body resistance or static electricity Meets the requirements of TR53, ANSI/ESD STM97.1 Meets the requirements of STM97.2 and IEC61340-4-5 |

|

|

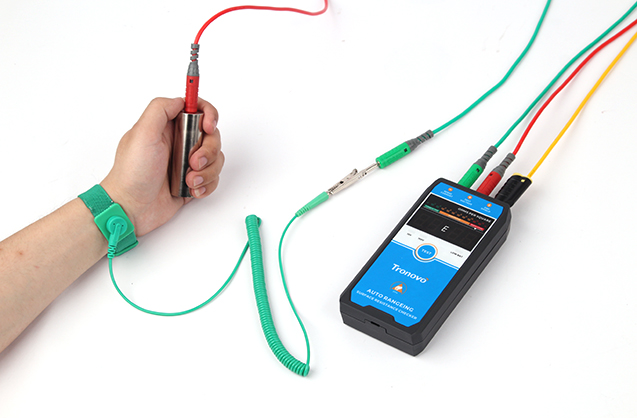

Wrist Strap - System Resistance Compliance VerificationConnect the ground wire to the negative terminal (-) of the MR63 surface resistance tester. Connect one end of the red test lead to the positive terminal (+) of the MR63 Surface Resistance Tester and connect the other end of the test lead to the handheld electrode. |

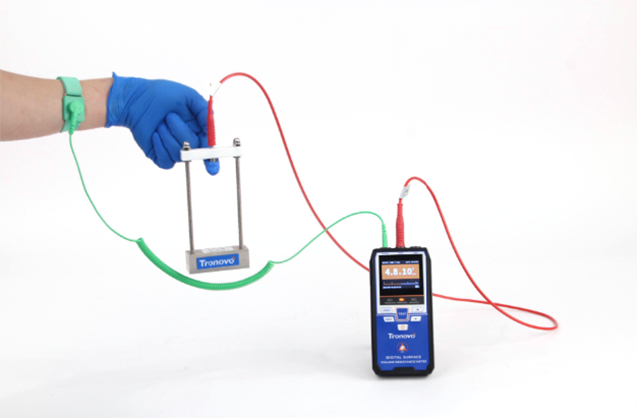

Gloves - System Resistance Compliance VerificationPlace the wrist strap on the gloved hand. Connect the wrist strap cable without 1MΩ resistance to one of the inputs of the MR63 Surface Resistance Tester. Connect the CAFE to the other input of the MR63 Surface Resistance Tester. Balance the CAFE on the fingerprint side of the finger of the selected thumb or gloved hand. |

|

|

Antistatic Screwdriver Resistance MeasurementInstall the connecting point probe on the test meter Place the antistatic screwdriver on an insulating plate and the two-point probe assembly on the area to be verified. Apply a downward force on the two-point probe assembly connected to the spring loaded electrode sufficient to complete the electrical connection. |

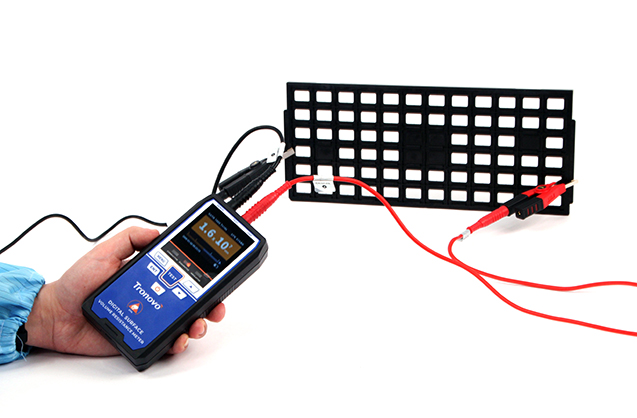

Anti-static pallet point-to-point resistance measurementAn end of the first test lead is connected to the negative terminal (-) of the MR63 Surface Resistance Measuring Instrument and the other end is connected to one end (-) of the black clamp electrode. One end of the second test lead is connected to the positive terminal (+) of the MR63 Surface Resistance Measuring Instrument and the other end is connected to the red clamp electrode end (+). Clamp the ends of the package area to be verified with the clamp electrodes. |

|

|

Footwear - Verification of System Resistance ComplianceConnect one end of the first test lead to the negative terminal (-) of the MR63 surface resistance tester and connect the other end of the lead to the foot electrode. One end of the second test lead is connected to the positive terminal (+) of the MR63 Surface Resistance Tester and the other end is connected to the handheld electrode. Hold the handheld electrode with one hand. One foot is placed on the foot electrode and the other foot is not in contact with the foot electrode or adjacent floor. |