MR63FT Anti-static Engineering Test Kit

Designed for anti-static engineering

Added Extension Rod Kit

No need to bend over to move electrode

|

New TFT large screen displaysDisplays resistance tail and index, temperature, relative temperature, and analogue pointer display function. Since humidity and temperature affect the electrical properties of the material being tested. Low temperature and humidity will increase the resistance value and slow down the dissipation time. Under high humidity conditions, a thin layer of water will condense on the surface of the object to be tested or be absorbed by it, and this hygroscopicity increases the electrical conductivity of the material, and this is especially true for materials that are highly water-absorbent. |

MR63 Digital Surface Volume Resistivity MeterThe MR63 is a comprehensive anti-static measuring instrument for checking surface and ground resistance, measuring the impedance or resistance of all conductive, antistatic, and electrostatic venting surfaces, as well as the relative humidity and temperature that affect electrical properties. |

|

|

New data logging and exporting - in a flash drive!Store and recall up to 99 measurements and support connection to a PC for exporting test data. |

TM-RME Extension Pole KitFor use with the TM-RM2 cylindrical electrode handle extension. Eliminates the need to bend over and move the ESD probe when testing ESD floors. Extension rod consists of three pieces that can be easily stored when not in use |

|

|

TM-RM2 Cylindrical Electrode AssemblyUsed to measure floor, table mat, clothing, chair resistance Used for point-to-point and point-to-ground resistance testing Meets the requirements of TR53 and ANSI/ESDS 20.20 Meets the requirements of ANSI/ESD STM2.1 Meets the requirements of ANSI/ESD STM4.1 Meets the requirements of ANSI/ESD STM7.1 Complies with ANSI/ESD STM12.1 Complies with IEC61340-5-1 |

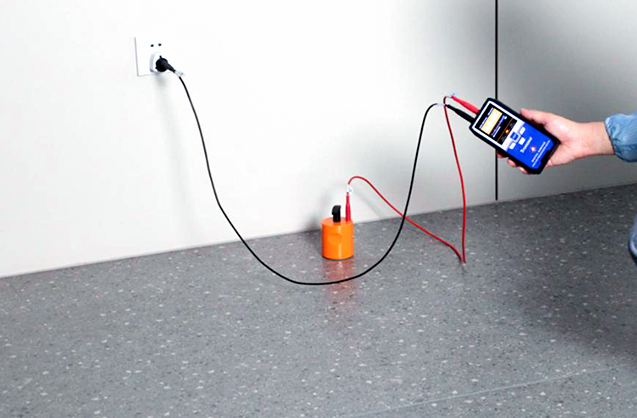

Flooring - System Resistance Compliance VerificationConnect one end of the first test lead to the negative terminal (-) of the MR63 Surface Resistance Tester and the other end to a previously verified ESD ground/connection reference point. One end of the second test lead is connected to the positive terminal (+) of the MR63 Surface Resistance Tester and the other end is connected to the resistance measurement electrode. |

|

|

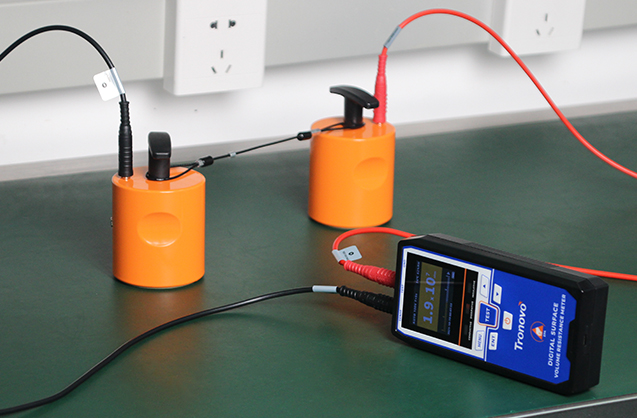

Point-to-point resistance measurement of table surfaceConnect the leads of the MR63 to the resistance measuring electrode. Place the resistance measurement electrode on the surface of the tabletop system under test and mark the distance between the two weights with a 10-inch test lead. Set the MR63 test time to 15 seconds, press the TEST button, wait for the countdown to end, and record the resistance value. |

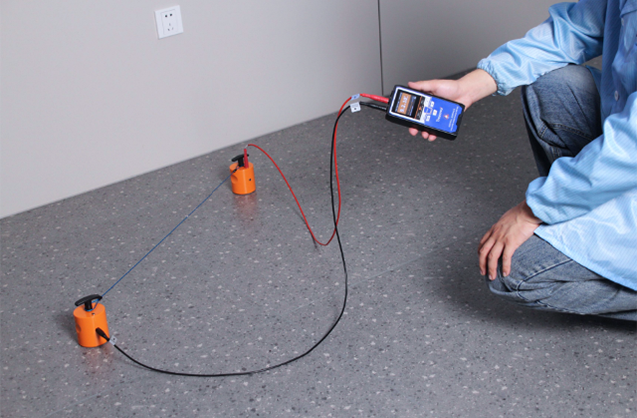

Flooring - Point to Point Resistance Compliance VerificationConnect the leads of the MR63 to the resistance measurement electrode. Place the resistance measuring electrode on the surface of the floor system under test and mark the distance between the two weights with a 36-inch test line. Set the MR63 test time to 15 seconds, press the TEST button, wait for the countdown to end, and record the resistance value. |

|