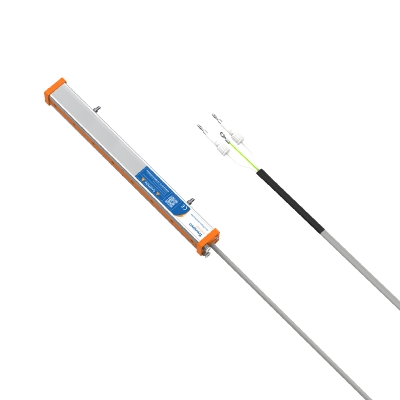

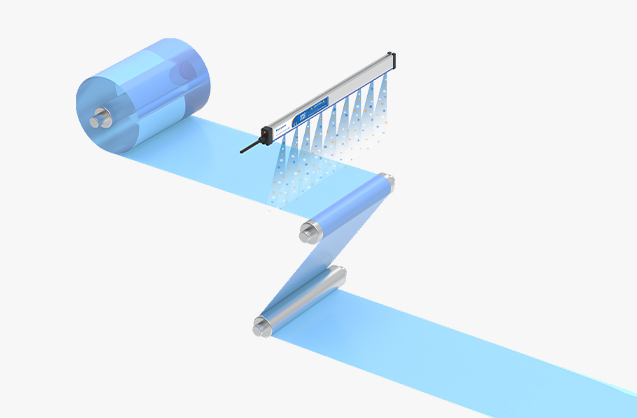

DB52H High Speed Airless Ionizing Bar

0

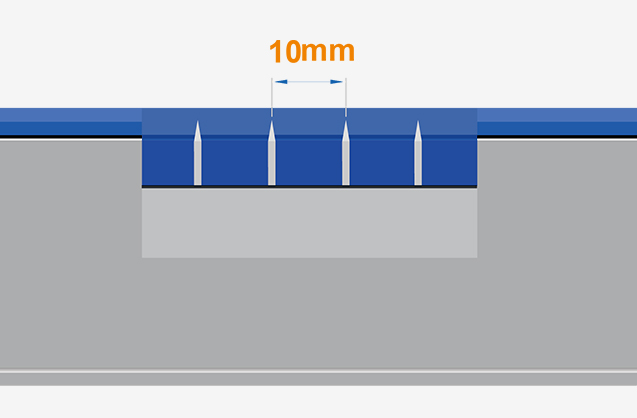

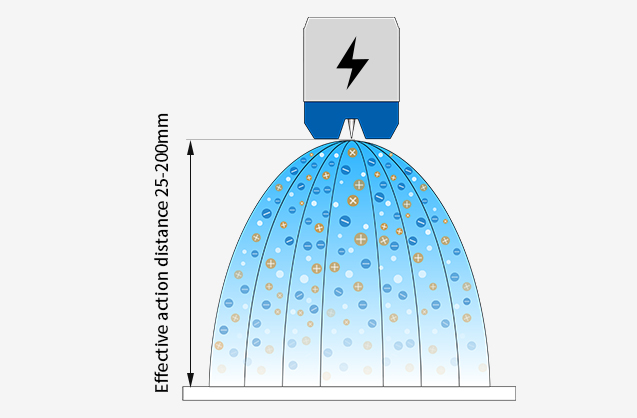

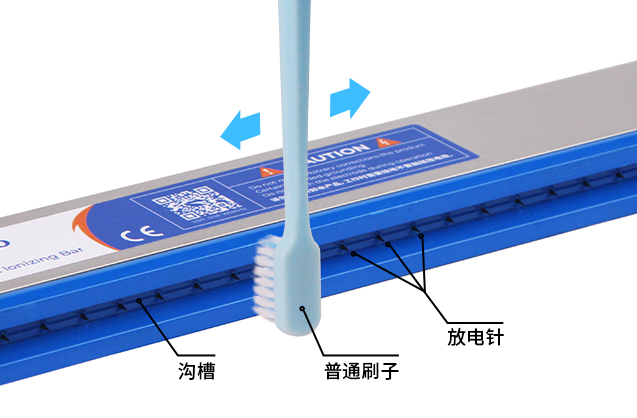

Innovative use of ultra-dense discharge needle and resistance coupling technology to achieve superb electrostatic elimination performance, the elimination speed is 2-3 times faster than traditional ion bars. Ion field coverage distance up to 20cm, even if installed at a distance can quickly neutralise high static charge, adapt to high-speed production lines, film winding and other demanding scenes. Pure tungsten emitter pin is corrosion resistant, long life, safe and no electric shock. Widely used in electronic manufacturing, printing and packaging, medical clean room and other fields, is a high-performance alternative to the traditional ion bar!