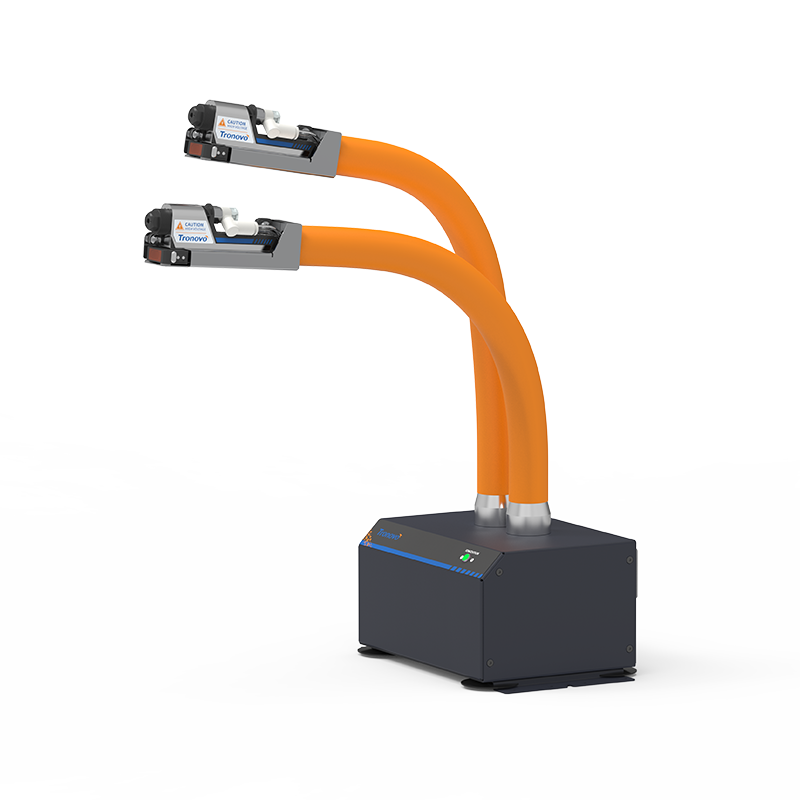

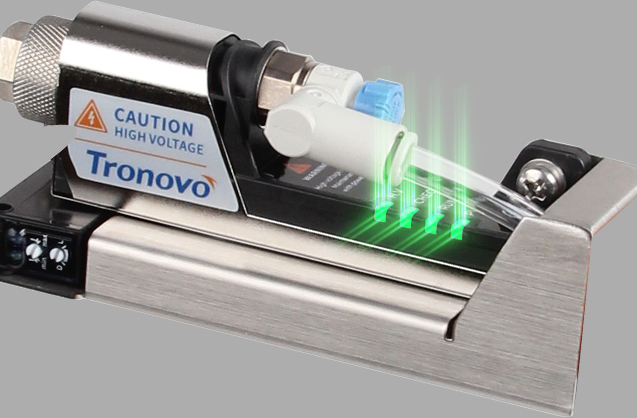

DN243 HF Ionizing Wind Snake

0

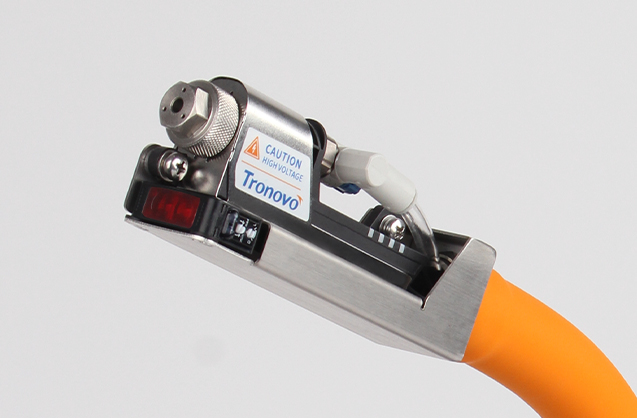

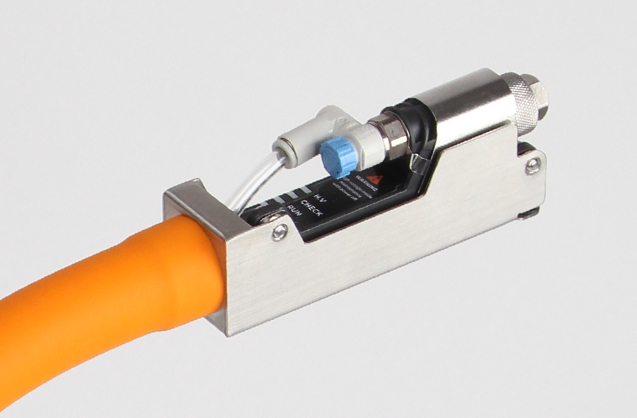

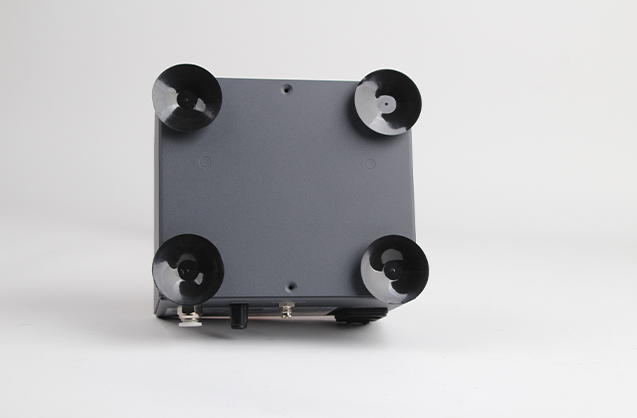

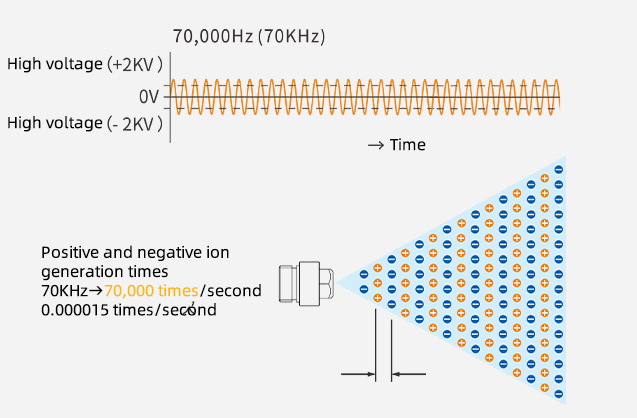

Pulse AC technology ion wind snake, efficiently solves the problem of static electricity elimination and industrial dust removal! Its unique structure ensures stable performance and strong adaptability, and it can work reliably in all kinds of production environments. Widely used in printing, packaging, plastics, spraying and other key areas, effectively removing static electricity adsorption and dust pollution. This not only significantly improves production efficiency, but also protects product quality. Choose the ionic wind snake, with cost-effective solutions, easy to deal with static dust problems, optimise your production line performance.