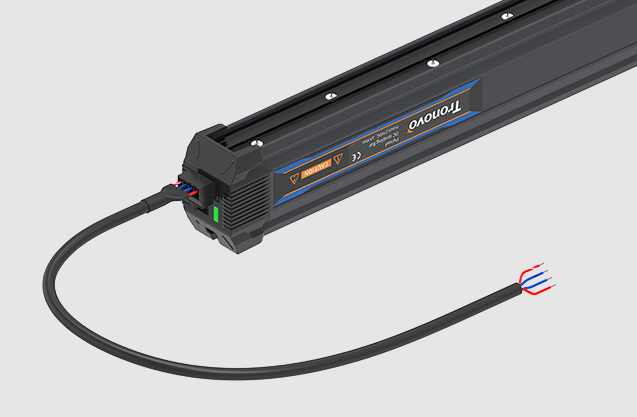

DB961 Ultra Performance Long Ionizing bar

0

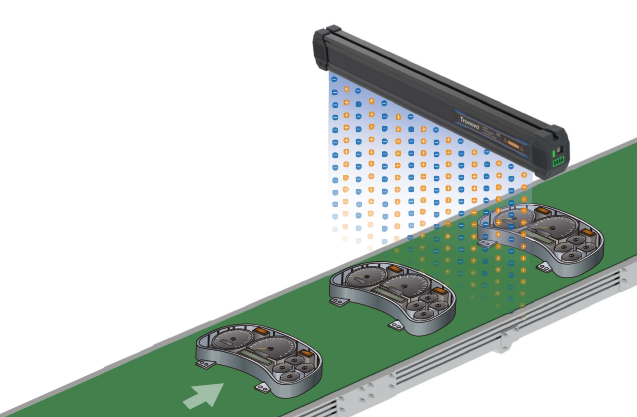

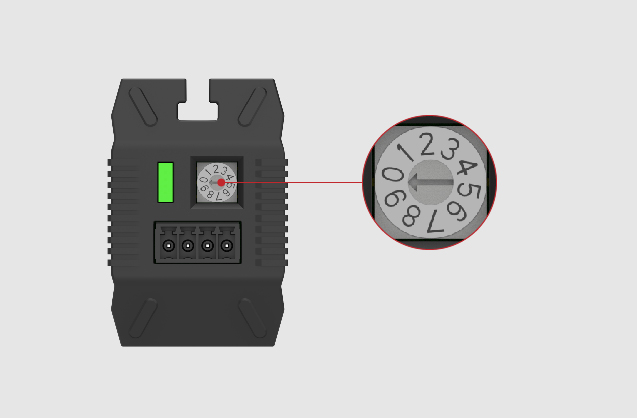

With pure tungsten ion needles (with a life expectancy of at least 30,000 hours) and an integrated high-voltage module, only 24V DC is needed for rapid neutralisation of static electricity in 0.5 seconds. The DC pulse technology increases the ion concentration by 50%, making it suitable for high-speed production lines (≤800 m/min), such as film rewinding and Li-ion manufacturing. The IP66 protection and wide temperature range make it suitable for use in harsh environments in the semiconductor and chemical industries. Real-time monitoring of the equipment is possible via the RS485/Modbus protocol, and the fault response efficiency is increased by 90%. With localised costs (saving 40% compared to imported products), it integrates with Industry 4.0 intelligent management to help enterprises reduce costs and increase efficiency. It is the ideal solution for intelligent static elimination in precision electronics and automobile manufacturing.