DB941 Short distance High Speed Ionizing Bar

0

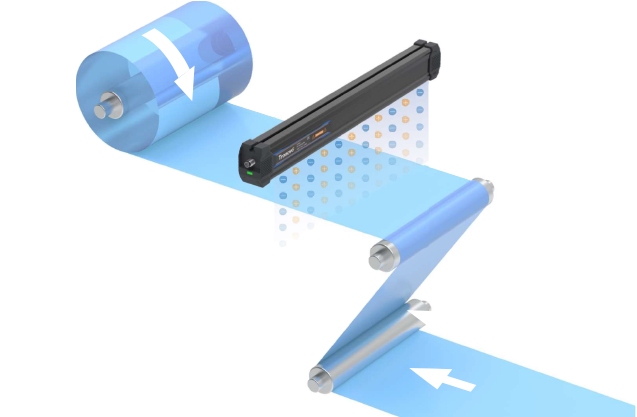

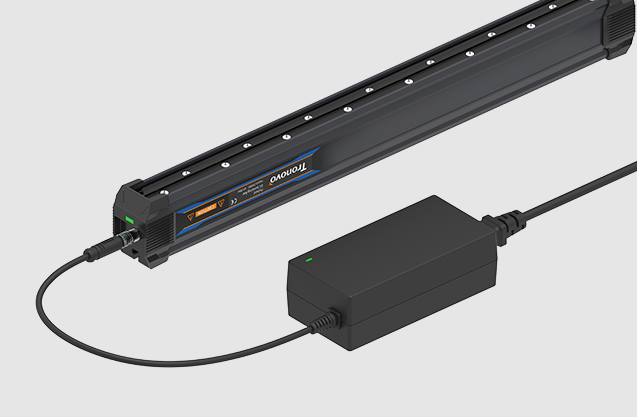

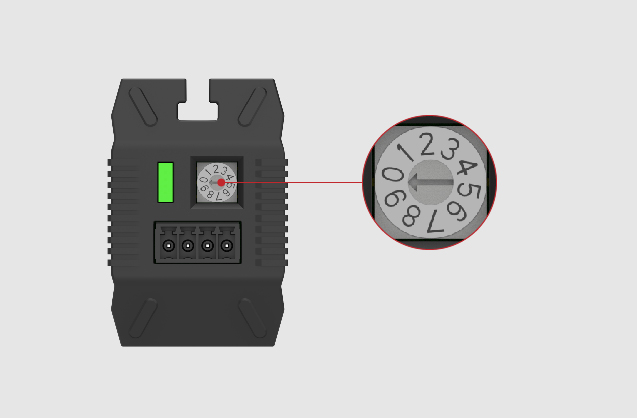

Adopting pulse DC technology, with independent positive and negative electrode needles that release a high-voltage electric field in turn, the efficiency of eliminating electricity is more than 200% higher than with traditional AC technology. The airless design and 5 cm ultra-thin body can be embedded in the slit of the production line, supporting windless silent de-static and avoiding airflow interference. This makes it suitable for clean rooms and high-speed coil scenes (600 m/min). The intelligent control system uses three-colour LED status lights (running/alarm/fault) and a PLC/RS485 communication interface to enable real-time monitoring and control and to adapt accurately to the needs of the production line. It is suitable for use in printing (to solve issues such as ink splash and colour registration inaccuracy), film slitting (to eliminate hundreds of thousands of volts of static electricity) and other high-precision applications. This extends the life of the electrodes and reduces maintenance costs.