DB921 Compact High Speed Ionizing Bar

0

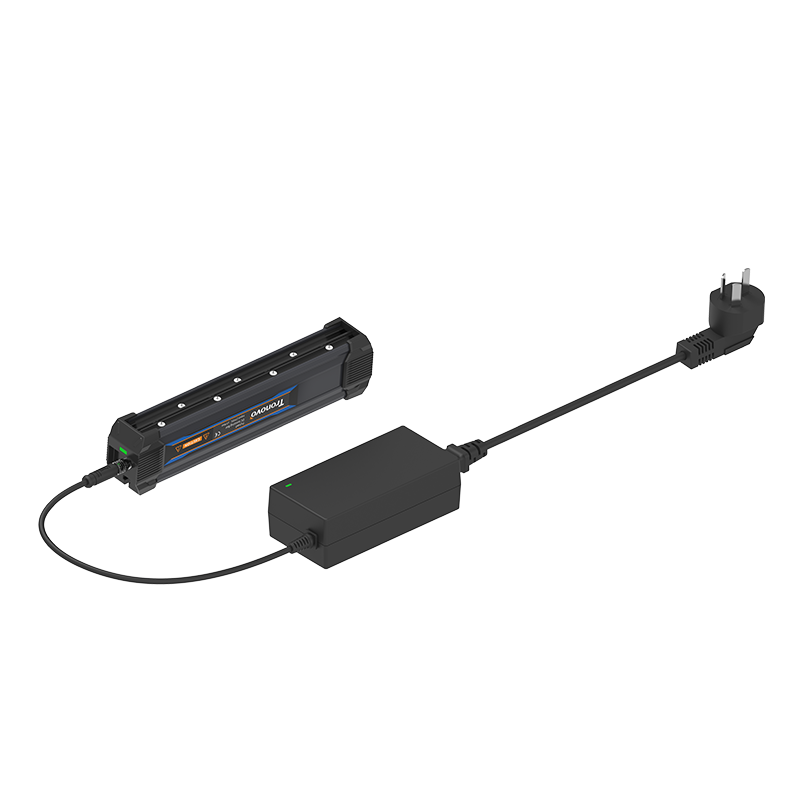

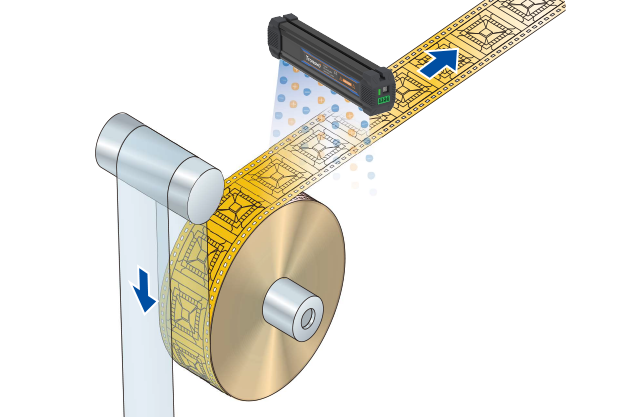

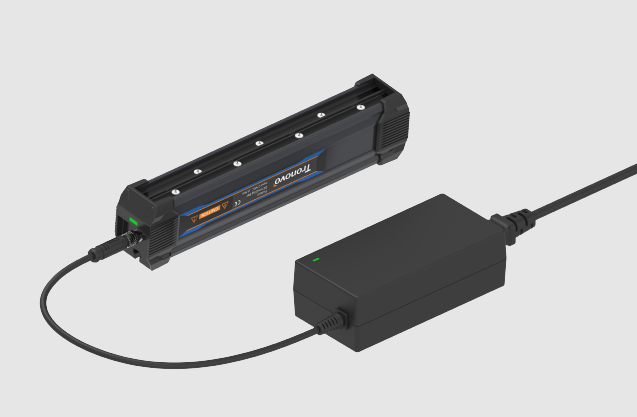

Designed for industrial scenarios, integrated high-voltage power supply, only 24v DC safe low-voltage input, convenient installation, simplified installation and wiring, and eliminate high-voltage hidden dangers. The use of rugged structure.equipped with DC pulse technology, static neutralization performance is strong, adapt to high-performance mechanical requirements. Support remote status monitoring interface, real-time feedback running data, maintenance worry-free.