Project Background:

In the process of film slitting, electrostatic accumulation is the core problem that affects product quality and production efficiency. Static electricity will not only cause the film to stick to each other, resulting in slitting wrinkles, uneven winding and positioning deviation, seriously affecting the slitting accuracy and yield, but also may cause electric shock to the operator due to instantaneous high-voltage discharge, which threatens safety and reduces work efficiency.

Solution:

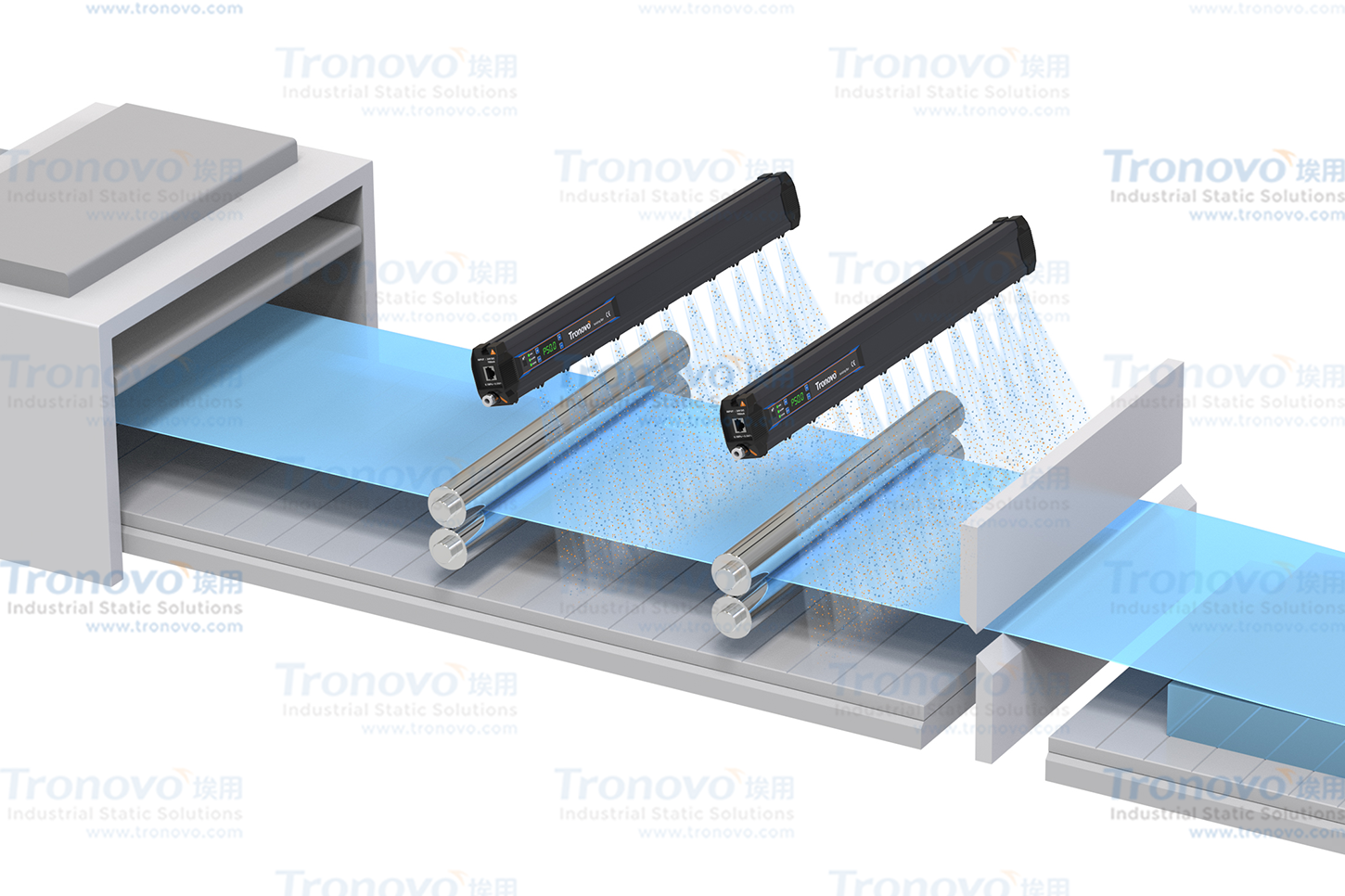

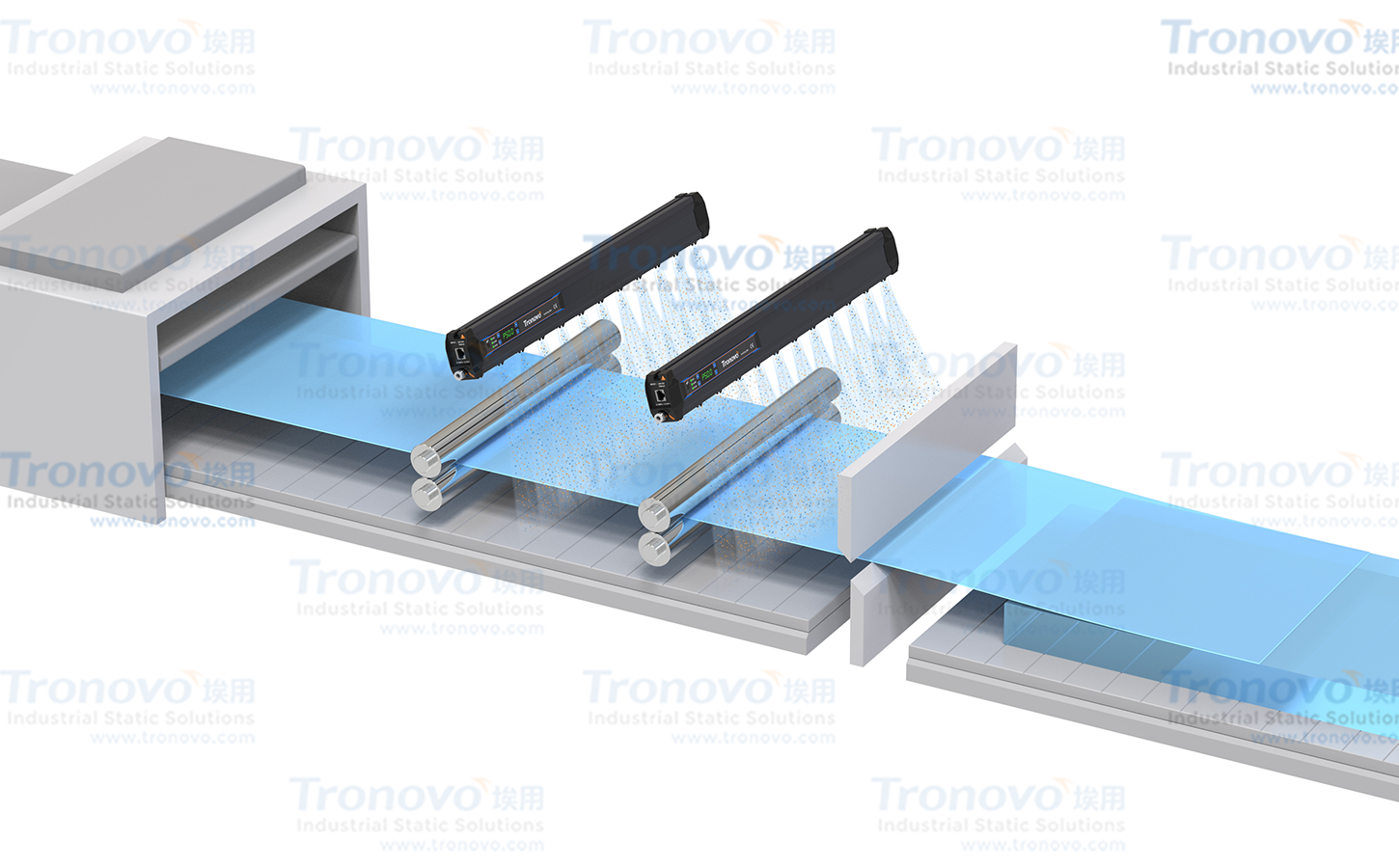

In view of these 1 pain points, pulse AC ionizer wind rods are recommend installed at the key stations of slitting and winding of the slitting machine. The static elimination rod can efficiently produce balanced positive and negative ion groups, accurately neutralize the electrostatic charge on the surface of the film, and fundamentally eliminate the phenomenon of adhesion and displacement. At the same time, with the clean air flow of directional coverage, the residual dust on the surface can be removed synchronously to ensure that the film is clean, dust-free, smooth and uniform during the slitting process.

Core advantages:

Compared with ordinary static eliminators, the ionizing wind bar has the advantages of fast neutralization speed, stable action, safety and reliability, and is especially suitable for high-speed slitting scenes. It is easy to install and can be seamlessly integrated into existing production lines, significantly improving slitting quality and operational safety, making it an ideal choice for enterprises to achieve efficient production and reduce losses.