Project Background:

In the process of high-speed film slitting and winding, electrostatic accumulation is the main problem affecting production efficiency and product quality. Static electricity will cause the film layer adhesion, resulting in untidy winding; adsorption of dust and particles in the environment, affecting the cleanliness of the product; may also interfere with sensitive electronic sensors, resulting in misoperation or even shutdown. These problems not only increase the production cost, but also become the key bottleneck of high-speed continuous production.

Solution:

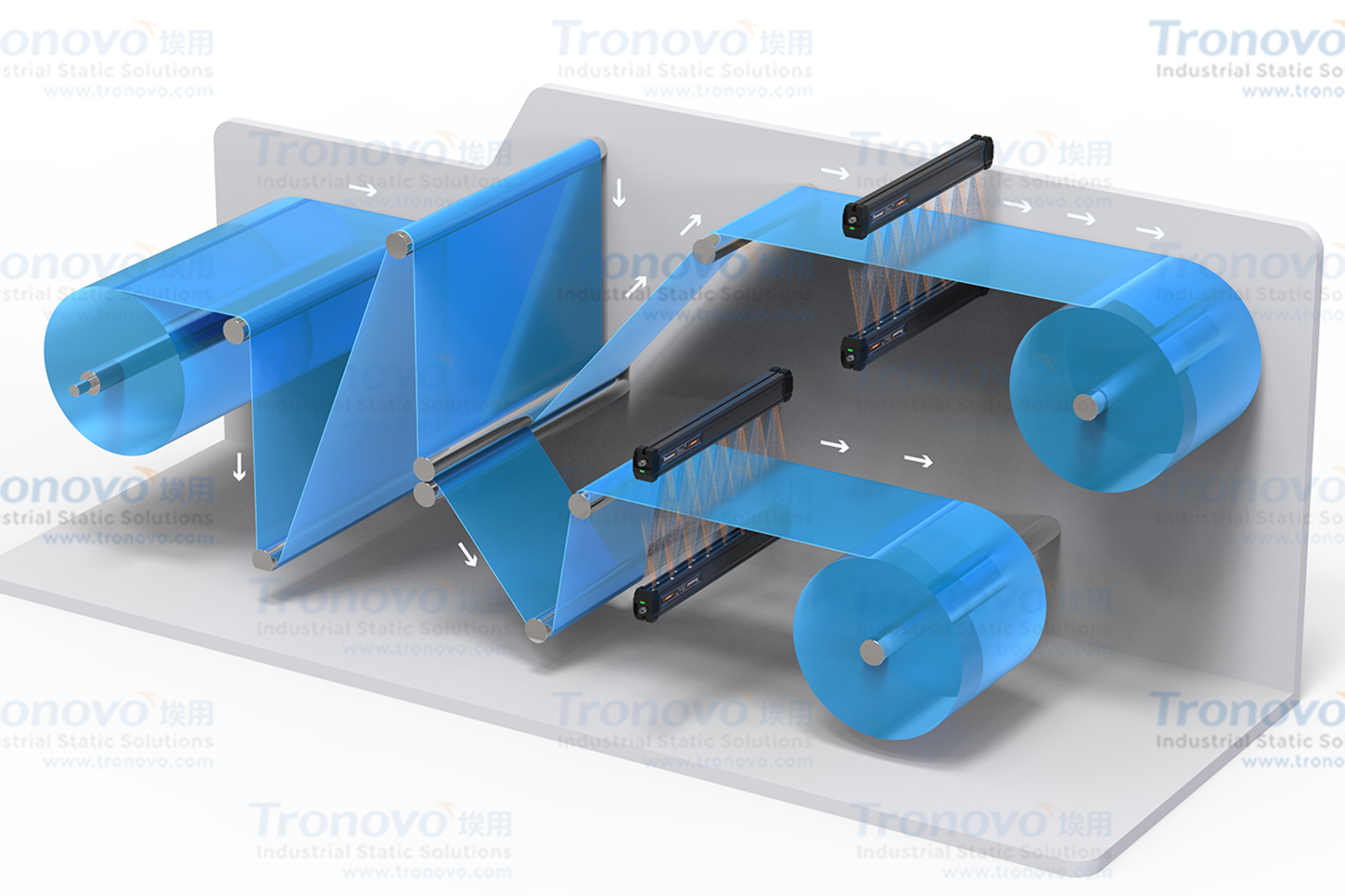

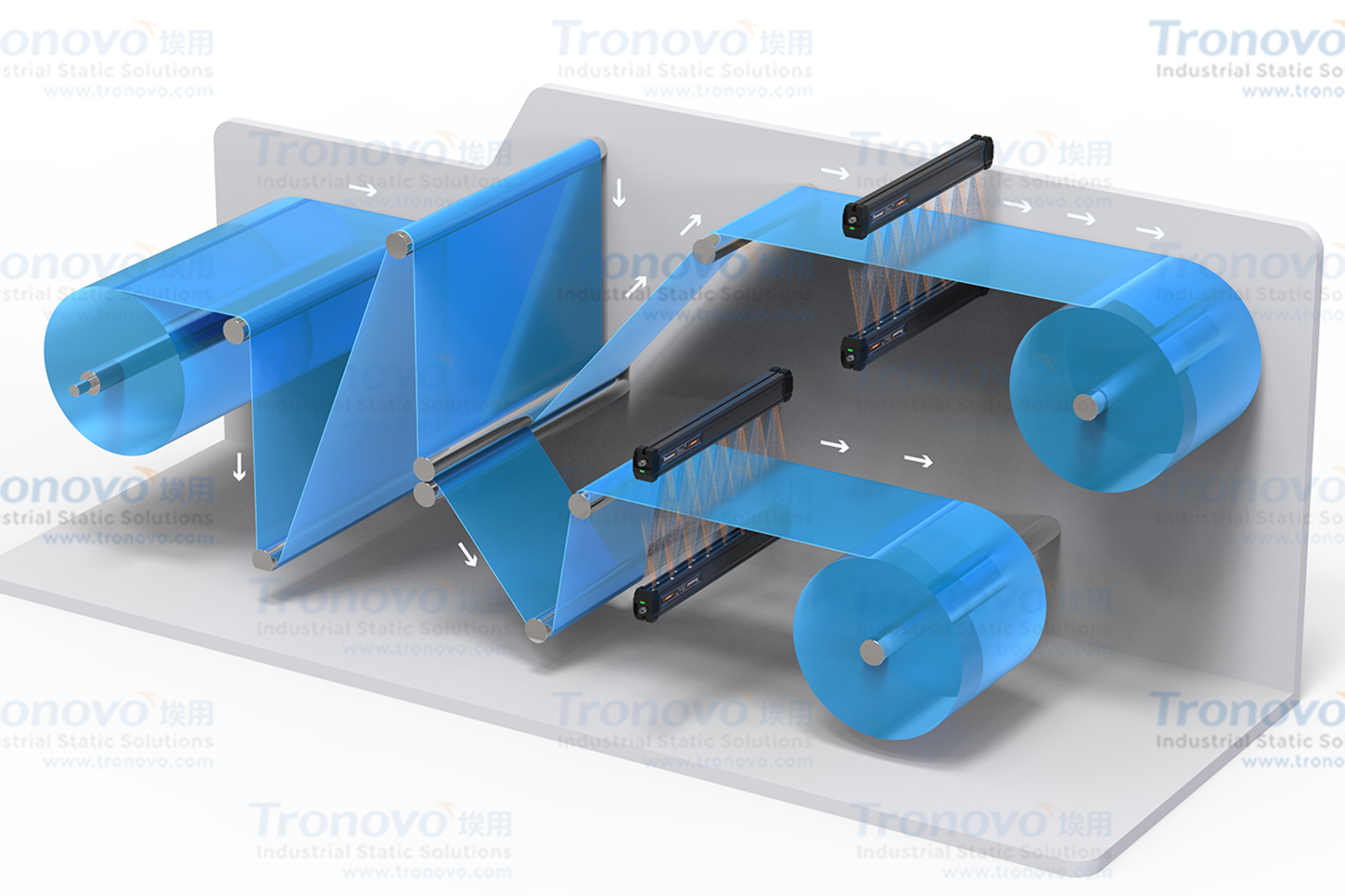

In view of the above challenges, the installation of pulsed DC ionizing bar near the film winding roll has become an efficient solution for a wide range of applications in the industry. The static elimination bar can quickly neutralize static charges by generating balanced positive and negative ions and uniformly transporting them to the surface of the film by means of a stable air flow. Compared with the traditional AC static elimination method, the pulse DC technology has higher ions balance, longer effective action distance and faster response speed, especially suitable for high-speed, wide film production environment.

Core advantages:

The practical application shows that the ion bar can significantly improve the winding quality, eliminate the phenomenon of coil deviation and edge unevenness, and improve the operation stability of the detection equipment. This not only helps enterprises to improve product yield and production efficiency, but also provides a key process guarantee for their intelligent and high-quality production.

Next:there is none left