Project Background:

In the high-speed slitting operation, a large amount of static electricity generated by the friction between the tool and the material has always been a pain point affecting the production efficiency and product quality-the material is not stacked and the surface is stained with dust due to electrostatic adsorption, which not only affects the subsequent process, but also brings safety and quality risks.

Solution:

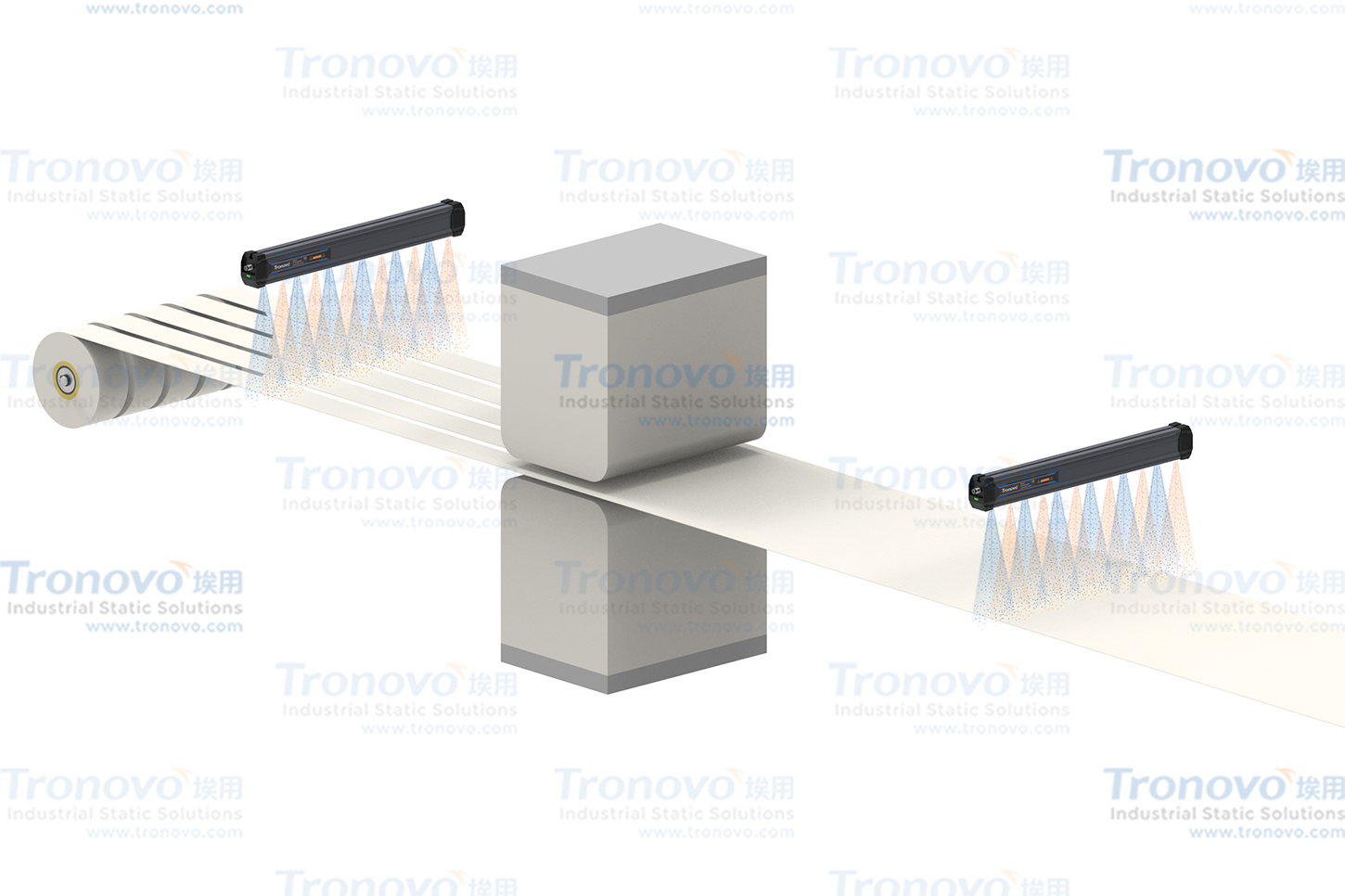

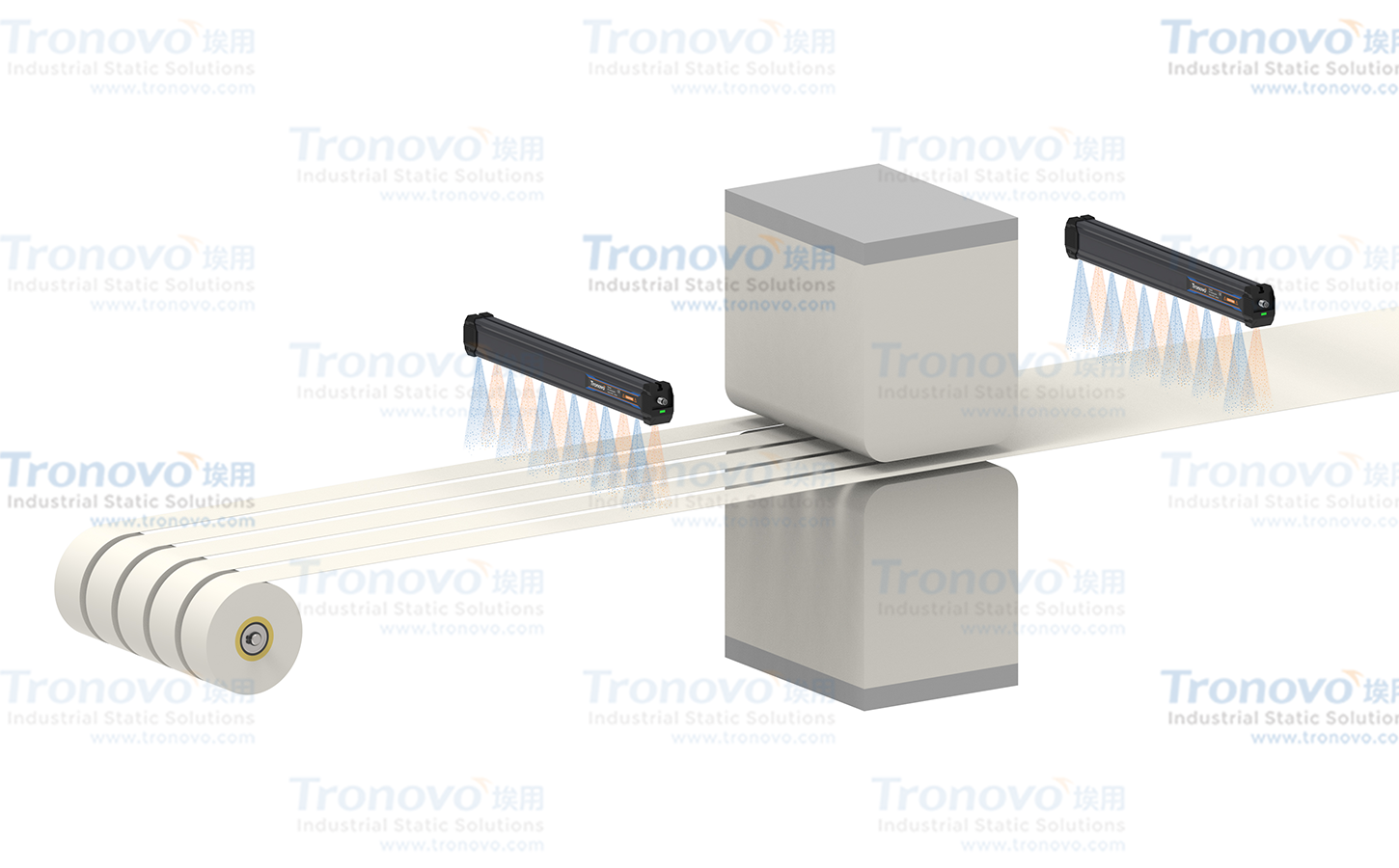

In view of these 1 problems, the pulsed DC ionizer bar shows significant application advantages. After being installed at the outlet position of the slitting tool, the static elimination rod can efficiently generate positive and negative ions flow, quickly neutralize the electrostatic charge on the surface of the material, and block the electrostatic adsorption phenomenon from the source. Compared with the traditional AC-type static elimination equipment, the pulse DC technology has a longer working distance and more uniform ionizing coverage, which can realize comprehensive power elimination for wide-width materials. The elimination speed can match the high-speed slitting process, and the electrostatic treatment can be completed at the moment of slitting.

Core advantages:

After slitting the material stack flat, no adhesion, greatly reducing the downtime finishing time; at the same time to avoid electrostatic dust caused by surface defects, significantly improve the product appearance pass rate. Ion bar adopts safe low voltage power supply, no risk of electric shock, in line with strict industrial safety standards, especially suitable for continuous, automated cutting production environment.