Project Background:

In the precision production of optical fiber winding, static electricity is always an "invisible obstacle" that threatens product quality and efficiency ". The surface of the optical fiber is easily charged after friction and separation operations, which will not only absorb dust and fluff in the air like a "magnet", causing surface pollution and directly affecting the stability of subsequent signal transmission. It will also cause "disobedience" to the optical fiber during winding-disorderly arrangement and mutual adhesion, greatly reducing winding accuracy and slowing down the production rhythm. More seriously, strong static electricity may penetrate the surface of the optical fiber, causing potential damage to the internal structure, shortening the service life of the product, and bringing hidden losses to the enterprise.

Solution:

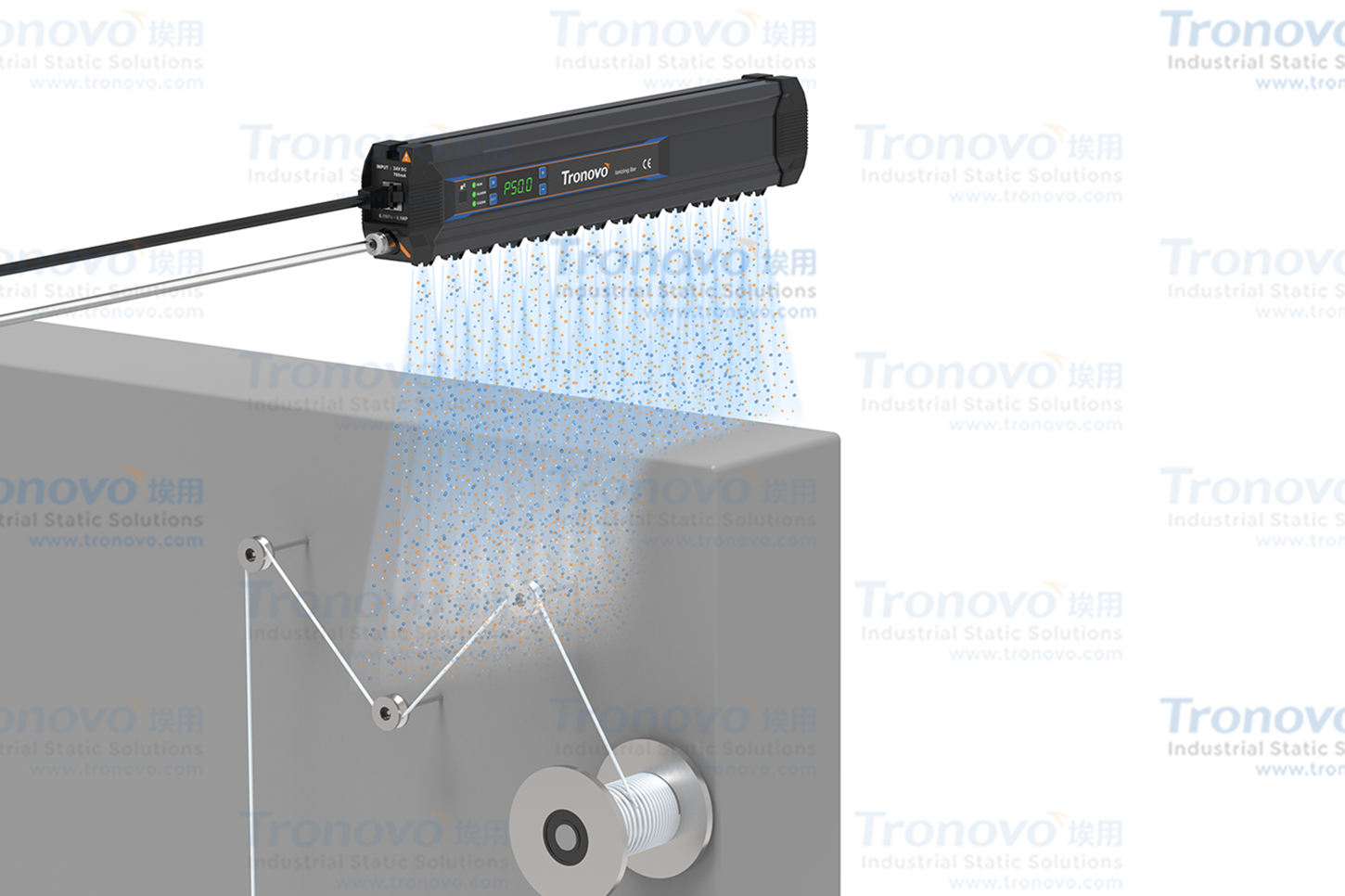

In view of these 1 pain points, we give a precise solution: a special pulse AC static elimination rod is installed at the inlet of the optical fiber winding equipment. The static elimination rod does not simply neutralize static electricity, but completes the "double action" at the moment when the optical fiber passes by by releasing the directional positive and negative ion airflow-quickly neutralizing the surface charge, blowing away the adsorbed tiny impurities at the same time, allowing the optical fiber to enter the winding link in a clean and stable state, thus avoiding the quality hidden danger from the source.

Core Advantages:

The coverage of the digital display ionizing bar is accurately matched with the incoming path of the optical fiber without any dead angle. The response speed of electrostatic neutralization is as fast as milliseconds, which perfectly matches the production rhythm of high-speed winding and does not slow down any process. In addition, the low-voltage safe power supply design is adopted, and the power consumption standard on the production site is strictly adapted to ensure efficient static removal, while building a strong safety line for operators, truly achieve "accuracy, efficiency, safety" both.