Project Background:

In roll film production lines for thin films, packaging materials, etc., static electricity is easily generated due to friction during high-speed unwinding and transmission. Static electricity causes uneven winding, material waste, and even fire hazards.

Solution:

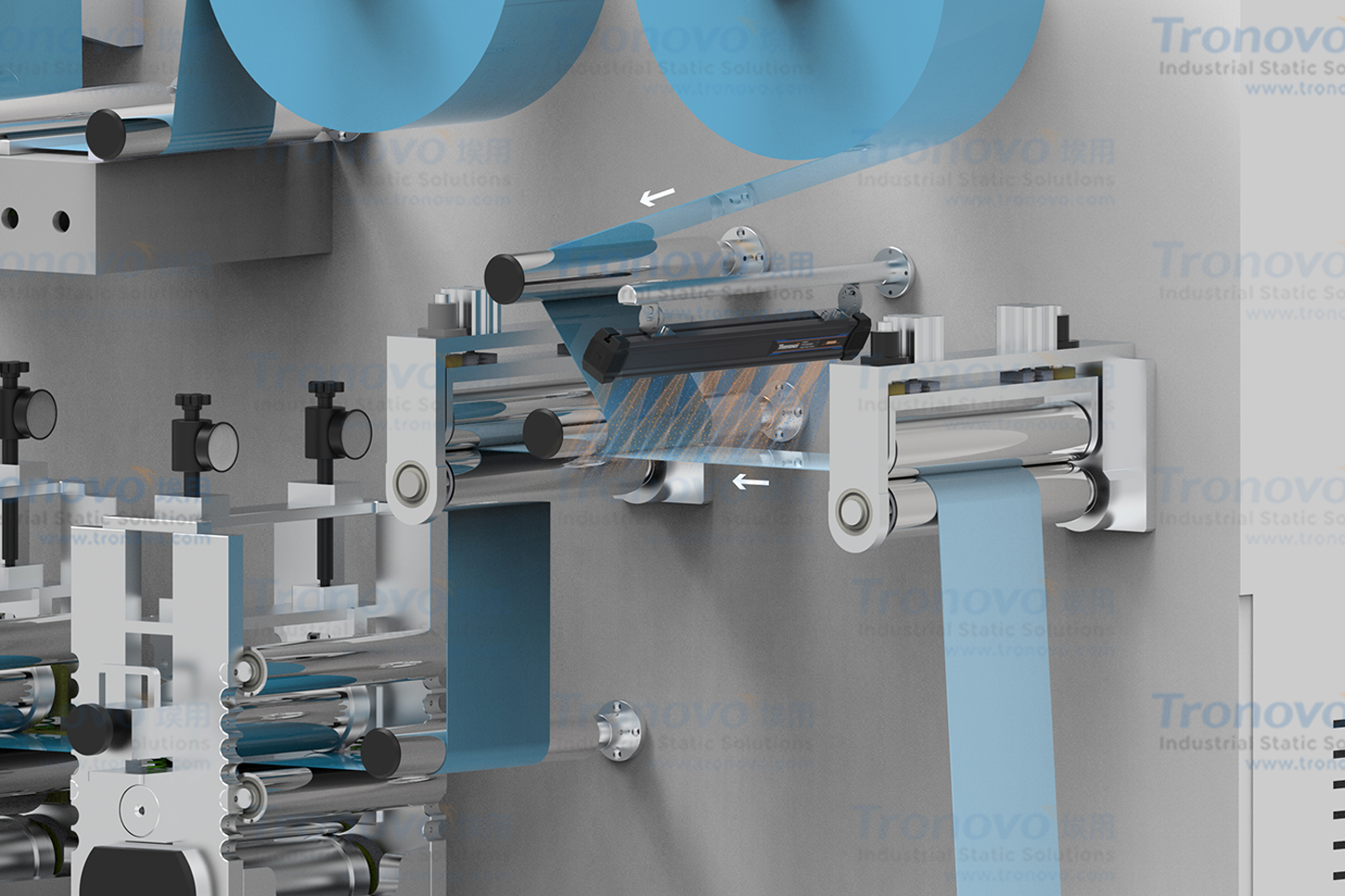

Precisely install ionizer bars above the roll film unwinding and conveying stations. The pulse DC bars continuously release a balanced flow of positive and negative ions, directly covering the entire surface of the roll material:

Core Advantages:

The positive and negative ion flow generated by the DC barinstantly neutralizes the static charge on the surface of the roll film, eliminating static adsorption force. The static value on the surface of the roll film is reduced to a safe range, completely solving the problem of misalignment during winding. The non-contact design avoids scratching the surface of the roll film, significantly improving the yield rate of high-transparency film materials, and is suitable for high-speed production lines.