Problem description:

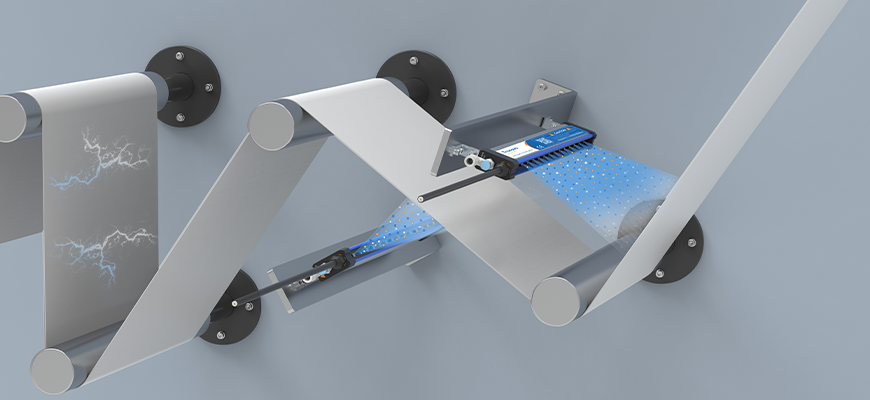

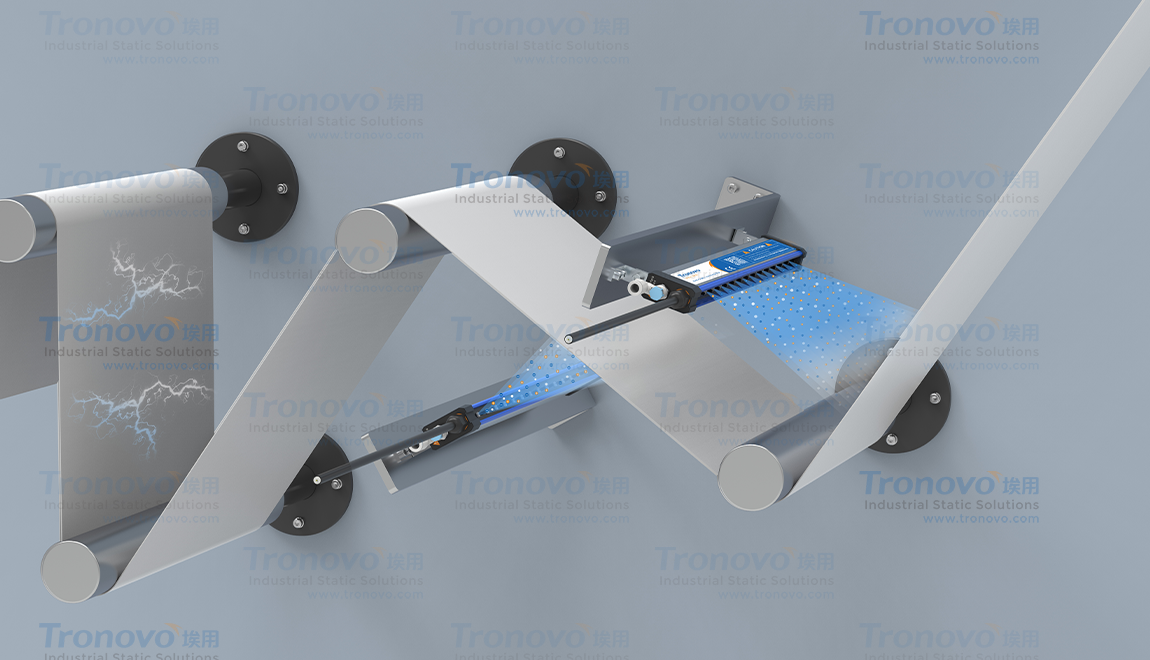

Charging is caused by peeling when the separator for lithium ion batteries is unfolded and friction when the roller is transported. The charged film will discharge near the roller, forming a pinhole in the film.

Solution:

Install a TR8630Pro ion bar on top and bottom after the diaphragm is peeled off. Reduce the static electricity generated during the peeling process and prevent the separator from breaking the separator due to discharge in contact with the metal roller.

Conclusion:

Electrostatic elimination of lithium-ion battery separators is an indispensable part of the battery manufacturing process. By adopting advanced static elimination technology and equipment, we can effectively solve the problem of static electricity and provide a strong guarantee for the safe, efficient and long-life operation of lithium-ion batteries. In the future, with the continuous development of lithium-ion battery technology, we have reason to believe that there will be more innovative technologies and methods in the separator in addition to static electricity, and contribute to the continuous progress of the lithium-ion battery industry.

Next:DC Rods in High-Speed Roll Film Production