DB522H High Power Ionizing Bar

production lines, and escort production efficiency and product quality.

|

Super Static EliminatorThe 25 mm ultra-dense ion needle electrostatic bar features a high-precision array design that increases the ion density by 50%. This makes it perfectly suited to high-speed production lines such as SMT mounter and film winding. Powered by a 24V low-voltage DC power supply for safety and energy efficiency, it avoids the risk of high-voltage electric shock. The built-in pure tungsten ion needles have a long life and an intelligent cleaning alarm function that reduces maintenance costs by 90%. |

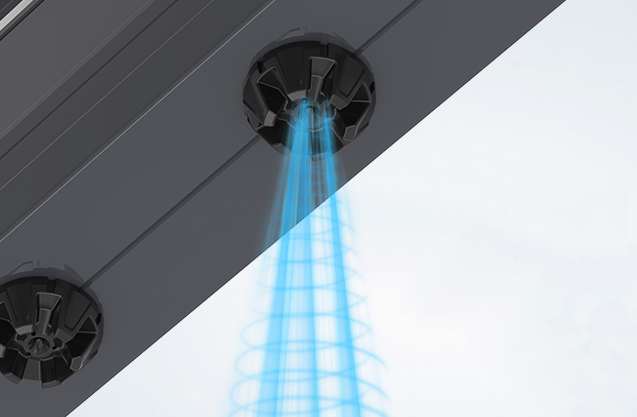

Discharge of air + large amount of ionsThe design of the high-density ion needle with a 25 mm pitch increases ion release by 60%. It is specially developed for the manufacturing of semiconductor wafers and OLED display panels. Its nano-scale dustproof structure effectively prevents particle deposition, making it especially suitable for precision processes such as chip encapsulation and flexible circuit board lamination. It provides stable, reliable electrostatic protection for front-end processes, reducing maintenance costs by 45% compared to traditional equipment. |

|

|

Easy to cleanThe innovative flat front-end design with a groove structure enables efficient one-touch cleaning. Simply use the soft brush to sweep along the groove to synchronise the tungsten alloy discharge pins and 0.3 mm precision nozzle depth maintenance, increasing cleaning efficiency by 70%. The 5-minute quick cleaning process extends the life of the equipment by 2000 hours and is the ideal low-maintenance static elimination solution for electronic assembly. This quick cleaning process extends equipment life by 2000 hours, making it an ideal low-maintenance static elimination solution for electronics assembly. |

Intuitive digital display and easy setupWith an industrial-grade display design and an integrated operation/alarm/clean three-colour indicator, the working frequency can be adjusted from 1 to 68 Hz and the ion balance calibrated from ±30 V using an infrared remote control or the host buttons (menu setting/+/- adjustment). It is equipped with a 6 mm gas supply interface and a pure tungsten ionisation needle array, and supports PLC communication for remote monitoring and control. It is especially suitable for SMT automatic production lines. |

|

|

Special nozzle structure long-lasting anti-dirt + air barrierThanks to its Clean Air Barrier Ion Needle Technology, the ion-generating area is physically isolated from the airflow channel by a patented air-electric separation design. This effectively blocks 99.7% of dust contamination. The dual-channel air supply system reduces electrode carbon buildup by 90%, extending the maintenance cycle to 2,000 hours and reducing maintenance time by 70%. |