DB522 Display Type Ionizing Bar

production lines, and escort production efficiency and product quality.

|

Super Static EliminatorThe new pulse AC ioniser uses advanced technology and has an adjustable ion balance (±35 V), which eliminates static electricity more efficiently. The multi-level frequency intelligent adjustment adapts to different distance requirements to ensure stable de-static performance. The replaceable ion needle design reduces maintenance costs, and the cleaning alarm and PLC control make automation more convenient. |

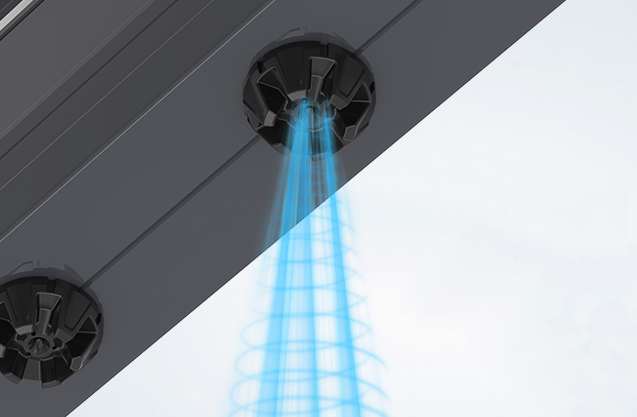

Discharge of air + large amount of ionsIt adopts high-frequency pulse technology, releasing millions of ions per second and increasing the speed of de-electricity by 50%. The ±35 V precision ion balance is perfectly adapted to harsh environments such as those in the semiconductor and FPD panel industries. The intelligent frequency adjustment covers lamination, leadframe and other micron-level process requirements. The visualised operation panel provides real-time alarms for abnormalities and reduces maintenance costs by 30%. |

|

|

Easy to cleanThe innovative flat design integrates the discharge needle and air blowing outlet into a groove structure. Only a light brush is needed to clean the product, increasing maintenance efficiency by 50%! The air blowing outlet is cleaned in sync to ensure stable airflow output, extending equipment life by three times! |

Intuitive digital display and easy setupIt is equipped with a high-definition display for real-time monitoring of equipment status and supports frequency adjustment and ion balance precision settings (±35V). The mainframe button or infrared remote control can be used for safe operation, and the menu settings are intuitive and convenient. The Φ6 mm air supply connector ensures stable airflow and, with the replaceable ionising needle design, maintenance is hassle-free. |

|

|

Special nozzle structure long-lasting anti-dirt + air barrierThe innovative air-electricity separation structure is equipped with a clean air barrier ionisation needle and 360° circular airflow to isolate dust. Performance attenuation is reduced by 70%! The special anti-fouling nozzle design reduces contaminant build-up and extends maintenance intervals by three times. It provides a durable and stable static elimination programme for precision electronics and semiconductor production. |