You may also be interested in these products

Product Parameter

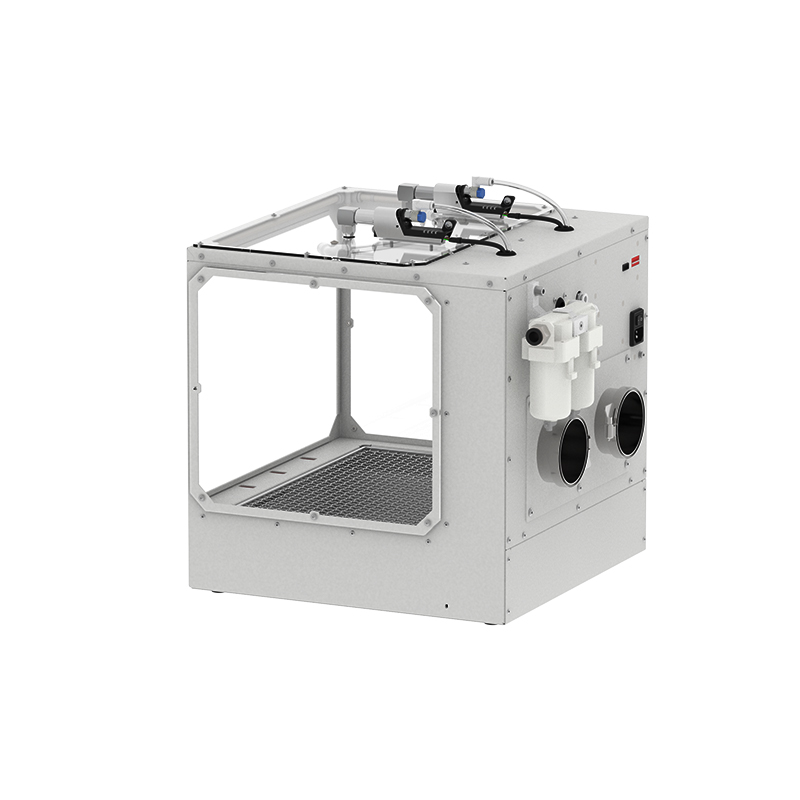

- Model

- ED442

- Size

- 400X400X400mm

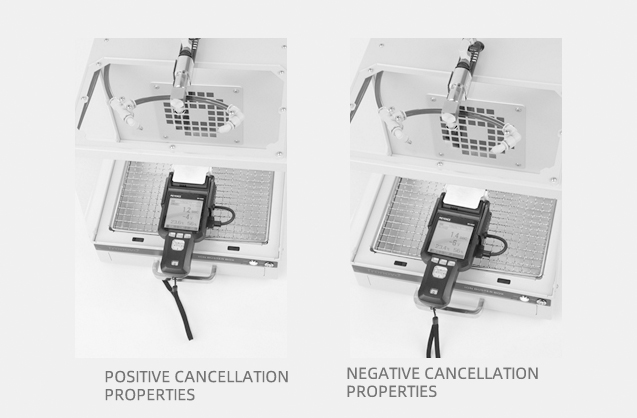

- lonizing

- 2 Nozzle

- Discharge

- ±10V/≤0.5S

- Technology

- High-frequency AC

- Squirting method

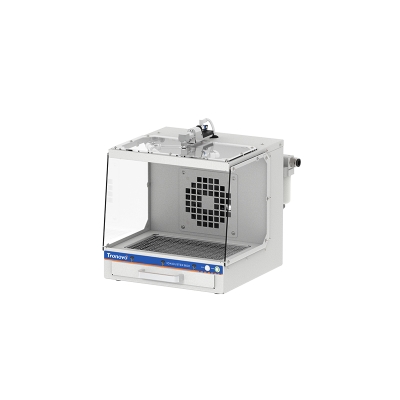

- Upper air outlet

- Lighting mode

- Dust on the workpiece is also clearly visible

- Assists insufflation

- lmprove dust collection efficiency

- Wind curtain

- It can effectively isolate dust

- Working mode

- Time setting: Continuous, timer [2, 5, 10s, 15s]

- Dust is discharged

- ∅76 flange to dust bag or vacuum cleaner

- Body Material

- Stainless steel

- l/0 interface

- PLC, input and output signals

- Product power

- Single AC100~240V(50Hz/60Hz)50W

- Warranty

- One-year