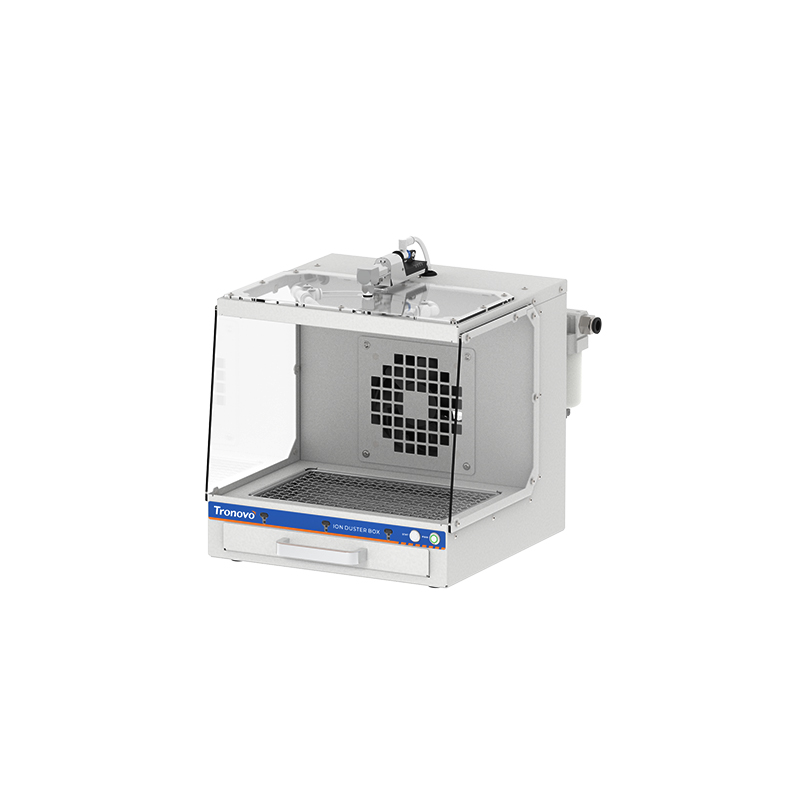

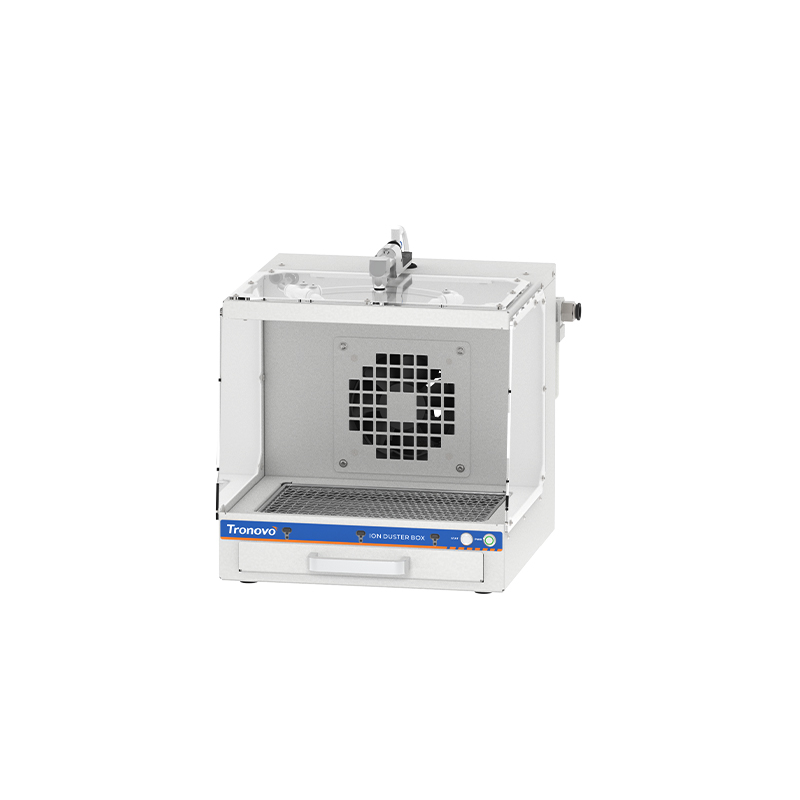

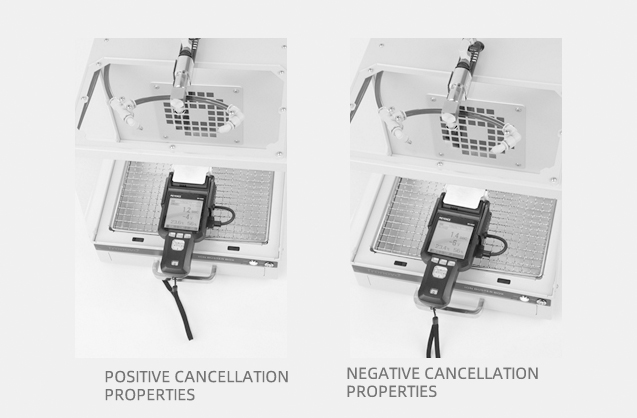

Specially designed for precision components such as electronic parts, smartphones, and lampshades, this system features an independent ion blower + high-efficiency dust removal dual system, achieving a dust removal efficiency of 99.9%. It simultaneously eliminates static electricity and collects dust, preventing secondary contamination. It meets the cleanliness standards of industries such as electronics and pharmaceuticals, and can solve static electricity accumulation and dust problems with a single button press.