Problem description:

In the process of preform injection molding, due to high-speed extrusion and friction, the surface of the preform is prone to generate static electricity, adsorbing dust, fibers and other small foreign matter in the environment. If these pollutants are attached to the surface of the preform, they will cause product defects in the subsequent blowing and filling processes, such as black spots on the bottle body and decreased transparency, which will seriously affect the appearance and hygiene standards of the product, resulting in a decrease in yield and an increase in production costs.

Solution:

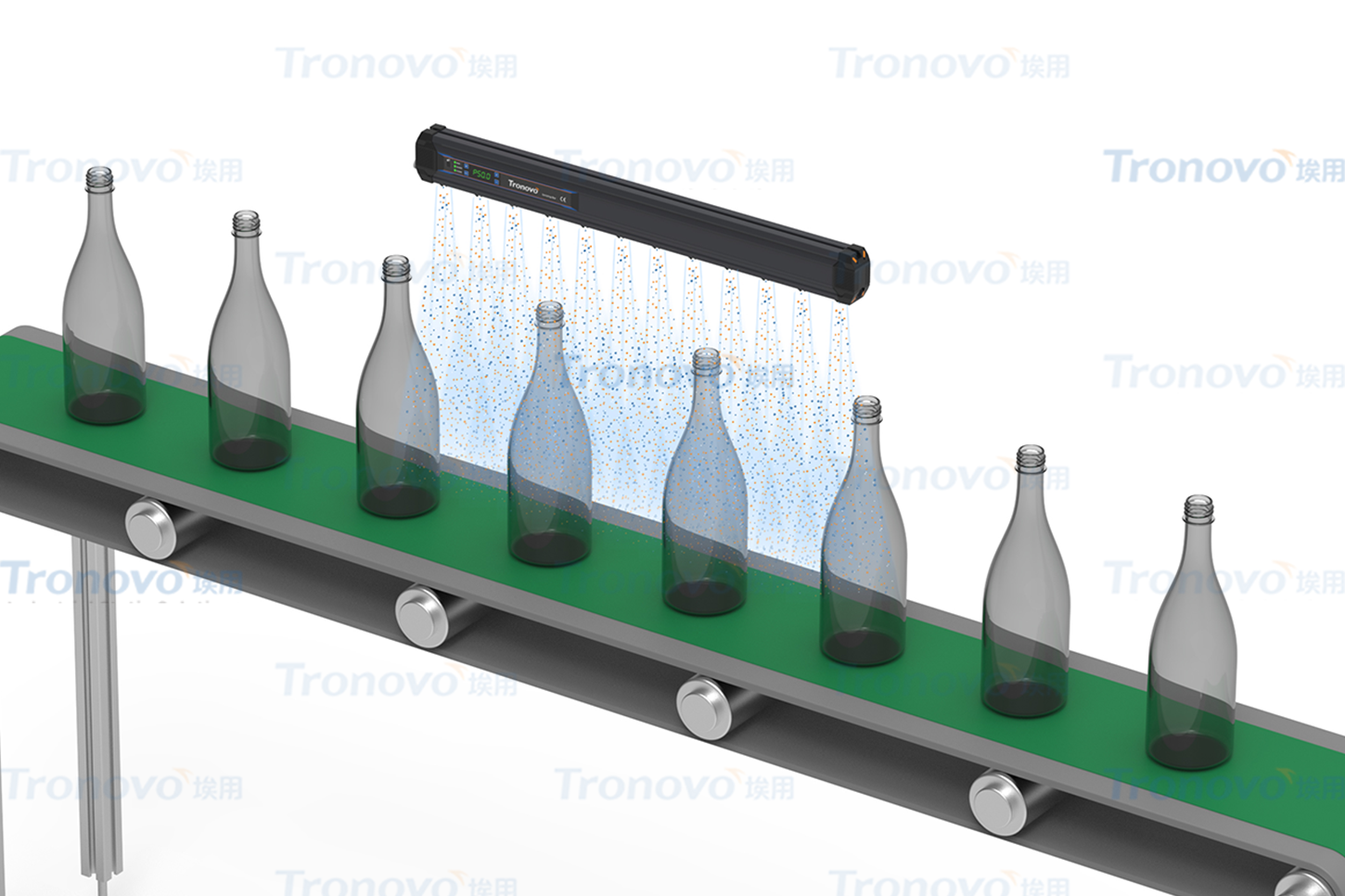

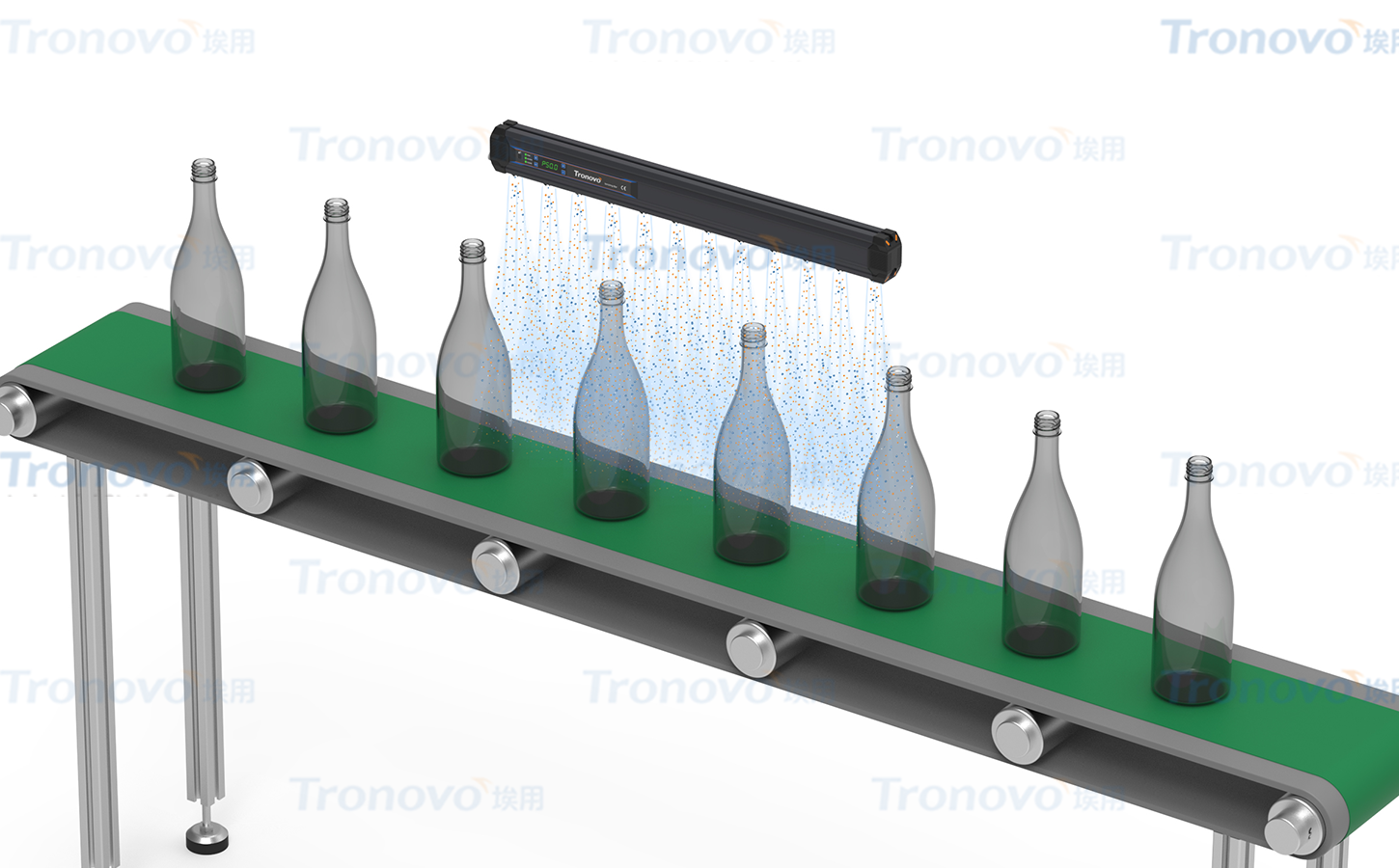

A bottle blank production enterprise introduced pulse AC ion bar, installed in the position of the bottle blank conveying line. The digital display type static elimination rod by alternately releasing positive and negative ion flow, quickly neutralize the static electricity on the surface of the preform, fundamentally eliminate the phenomenon of electrostatic adsorption. The uniform ion flow coverage of the pulsed AC ion bar ensures that preforms of different sizes and shapes can be effectively treated without dead ends and residues, especially suitable for high-speed production lines. After application, the cleanliness of the preform surface was significantly improved, the foreign matter adhesion was reduced by more than 85%, the product defect rate was reduced by about 55%, the production efficiency and overall yield were significantly improved, and the customer complaint rate was greatly reduced.

Next:there is none left