Project Background

In the production of automotive bumper coatings, static electricity is easily generated on the substrate due to friction with equipment or material detachment during handling, pretreatment, and conveying. This can lead to the following issues: adsorption of dust and impurities, resulting in coating particles and pinhole defects; affecting the uniformity of paint atomization, leading to appearance defects such as sagging and orange peel; electrostatic accumulation also poses a risk of spark discharge, and rework and cleaning increase costs and affect efficiency.

Solution

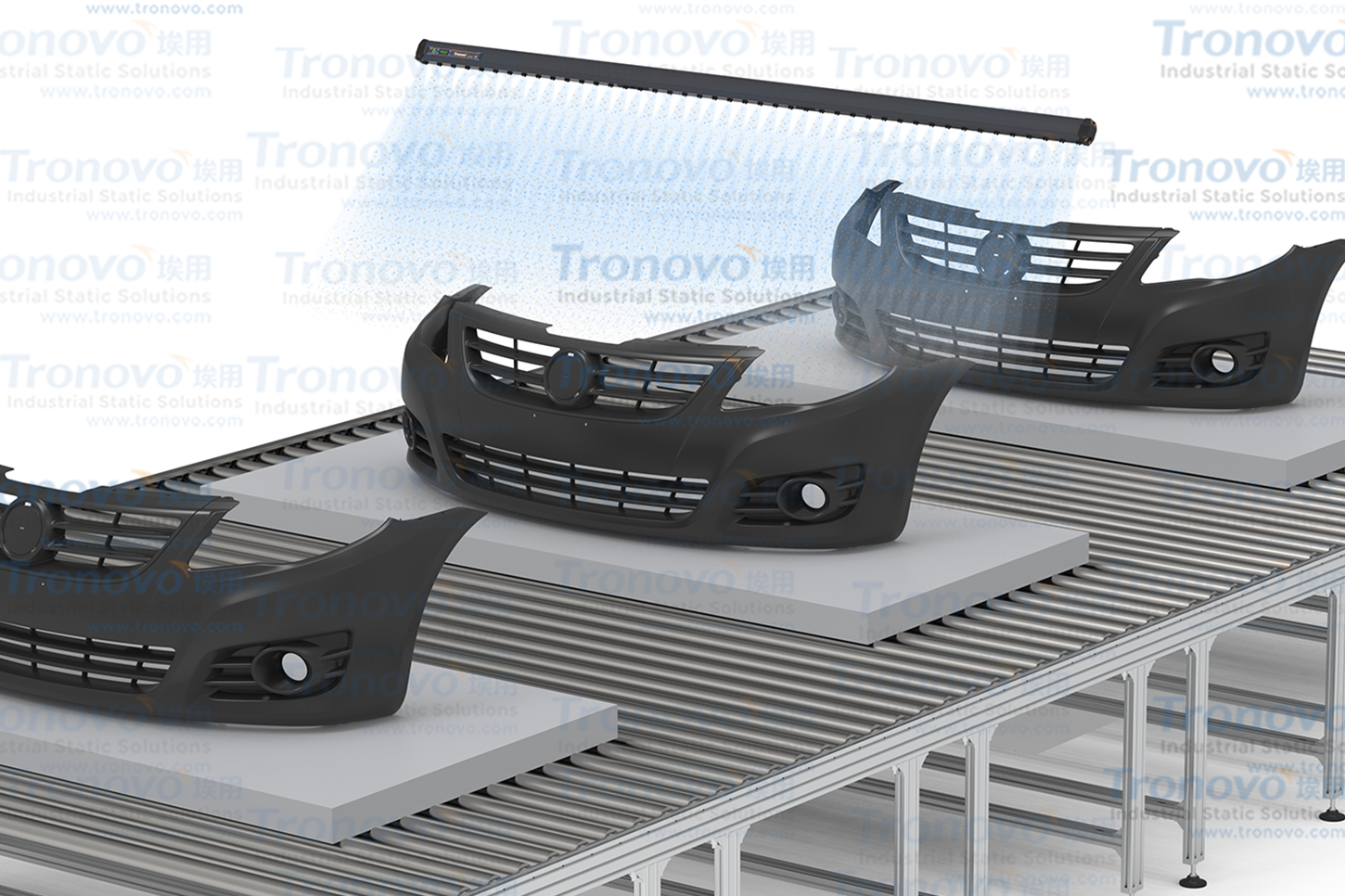

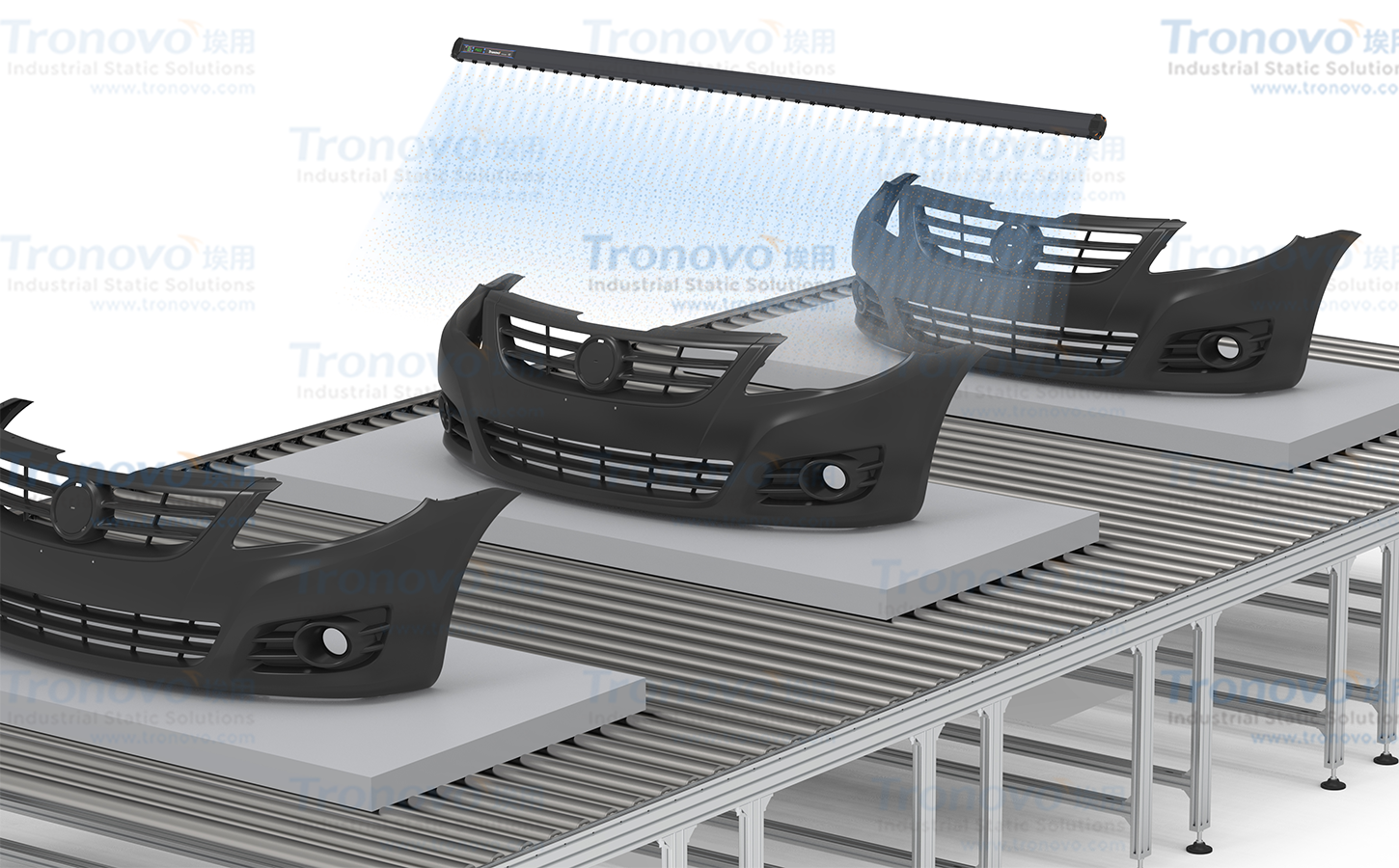

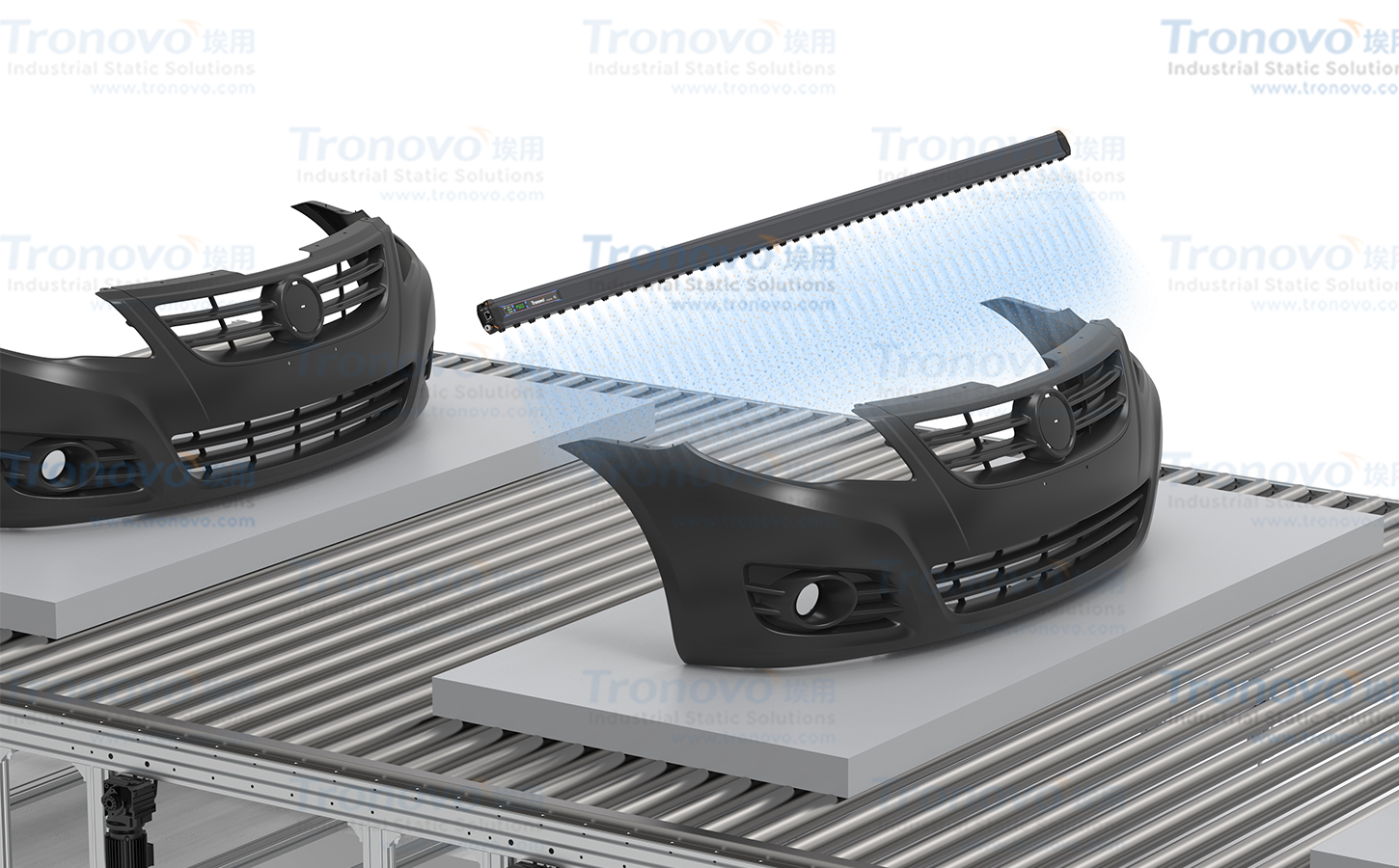

Targeted static elimination systems are deployed at key nodes in the bumper coating production line: Firstly, an electrostatic elimination rod is installed in the conveying section after the pretreatment of the bumper substrate and before entering the coating chamber, forming an ionized airflow barrier that covers the entire conveying process. This effectively neutralizes the static electricity on the substrate surface and prevents the adsorption of impurities in subsequent steps. Secondly, an AC electrostatic elimination rod is set up at the entrance of the coating chamber, precisely targeting the surface and edge areas of the bumper. It thoroughly removes residual static electricity through directional ionized airflow and simultaneously blows off attached impurities, ensuring uniform adsorption of paint mist and the quality of the coating surface.

Next:there is none left