Project Background:

In precision milling of wood panels, high-speed friction of the tool makes wood chips, wood powder due to electrostatic adsorption accumulation, causing multiple problems: charged wood powder attached to the surface of the workpiece, resulting in dimensional measurement deviation, surface roughness exceeds the standard, the finished product defective rate increases; electrostatic adsorption of wood powder in the spindle, the circuit at the accumulation of triggering the circuit alarms, equipment shutdowns; charged workpiece for painting, laminating and other processes, easy to adsorption of impurities due to electrostatic discharge, the emergence of pinholes, orange peel, poor lamination and other quality problems. When the charged workpieces are coated and laminated, it is easy for impurities to be adsorbed due to static electricity, resulting in pinholes, orange peel, poor lamination and other quality problems.

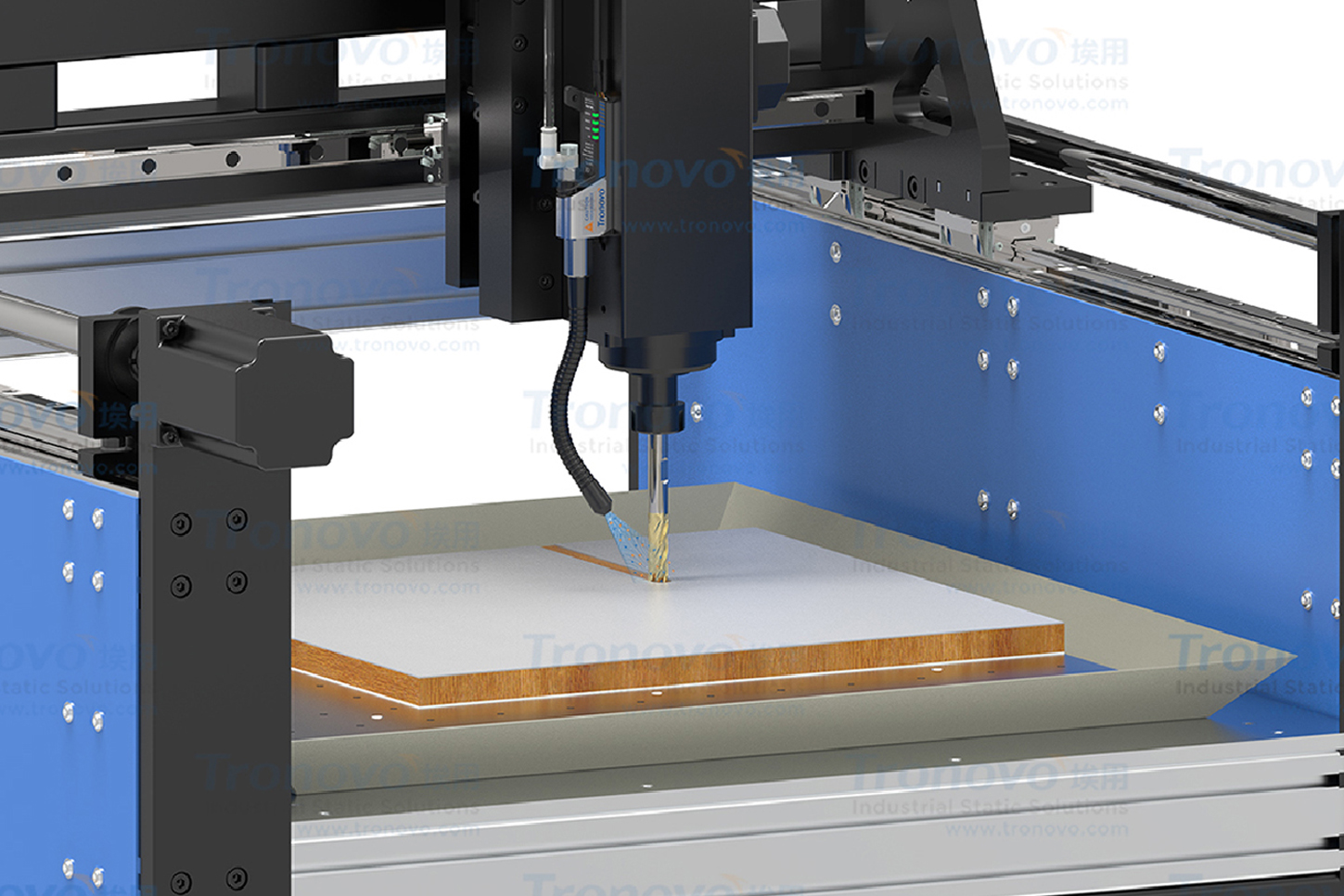

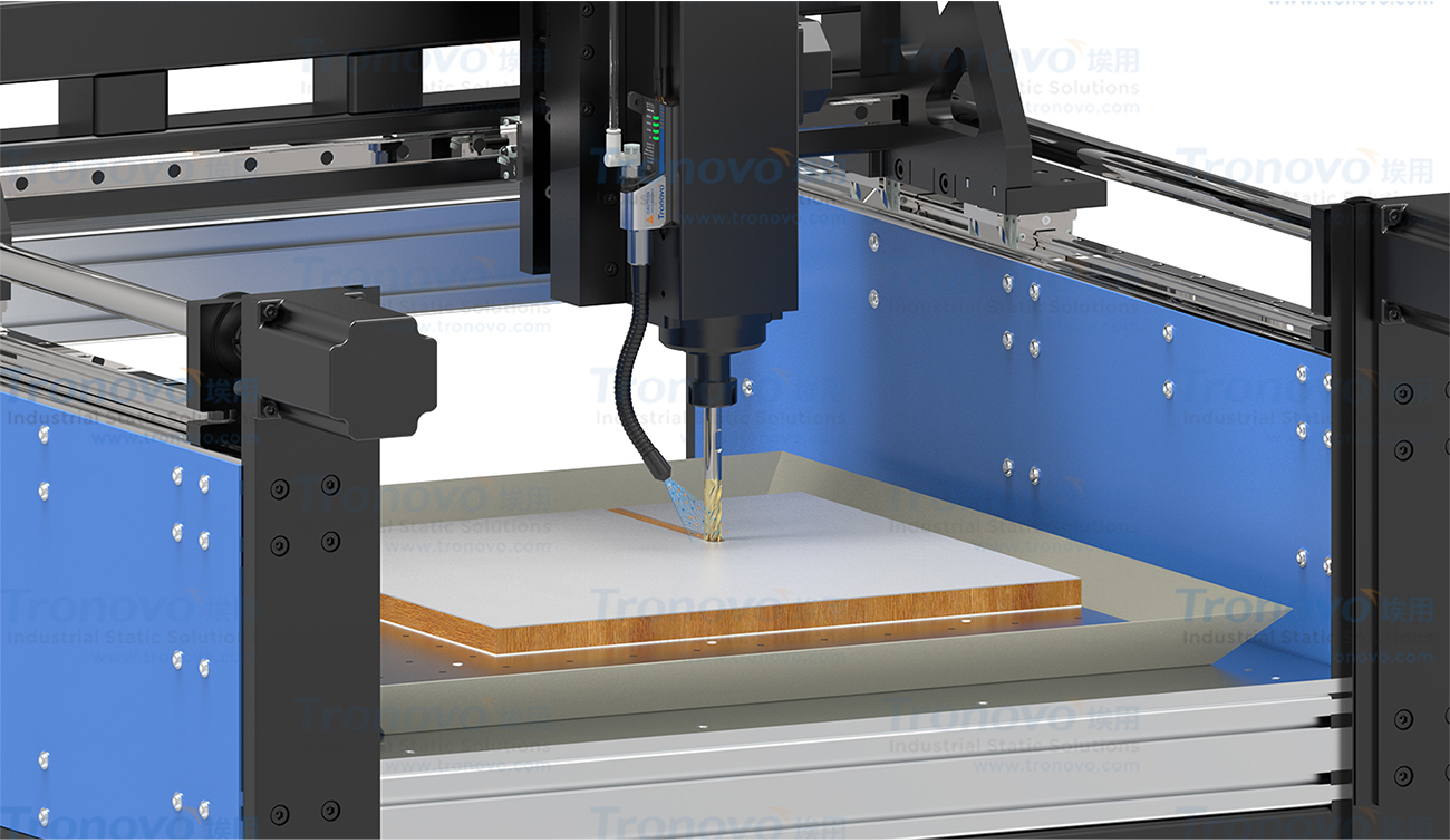

Solution:

Anti static Nozzle is mounted at the cutting position of the spindle tool; the ionized airflow blows off dust that has lost electrostatic adsorption, thereby achieving static elimination and surface cleaning in one go.

Core Advantages:

Precisely covers the cutting point; acts directly on the surface of charged objects with a static elimination time of less than 1 second; features a 24V low-voltage power supply, complying with machine tool electrical safety standards.