Project Background:

Metal/plastic pipes in the cutting, transmission process due to friction generated by static electricity, adsorption of environmental dust, resulting in surface contamination triggered by coating "fisheye", orange peel, decreased adhesion, coating defects, rework rate soared; electrostatic adsorption of debris to the installation of sealing ring deviation, assembly faults, seal failure.

Solution:

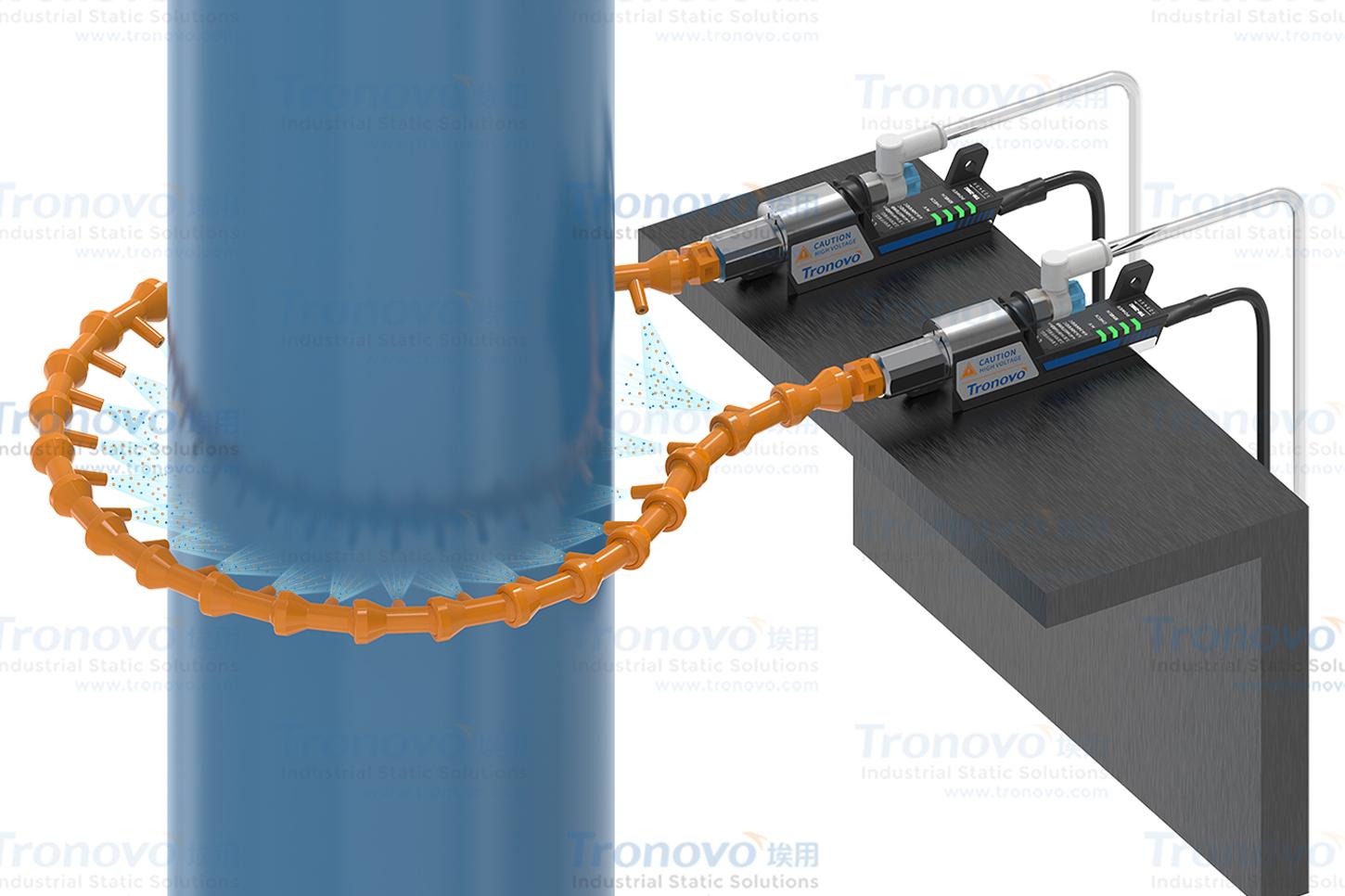

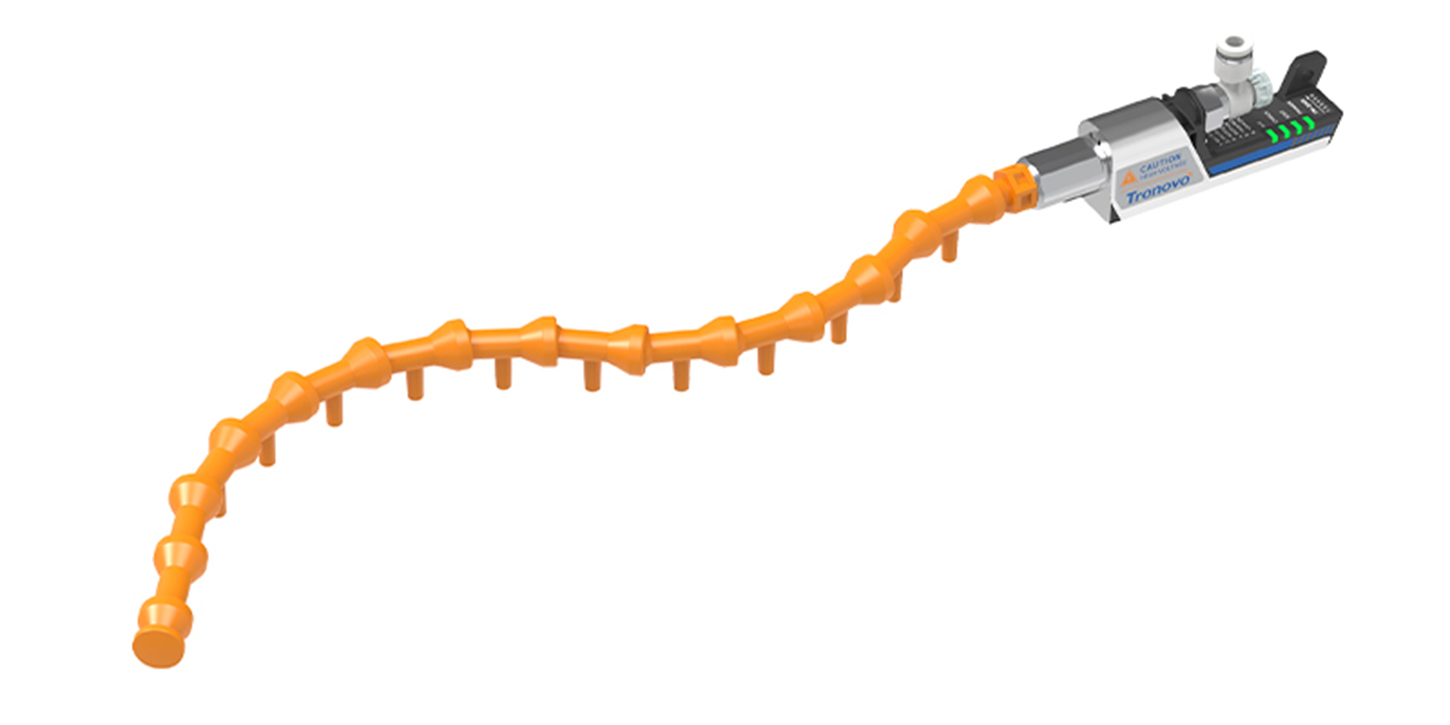

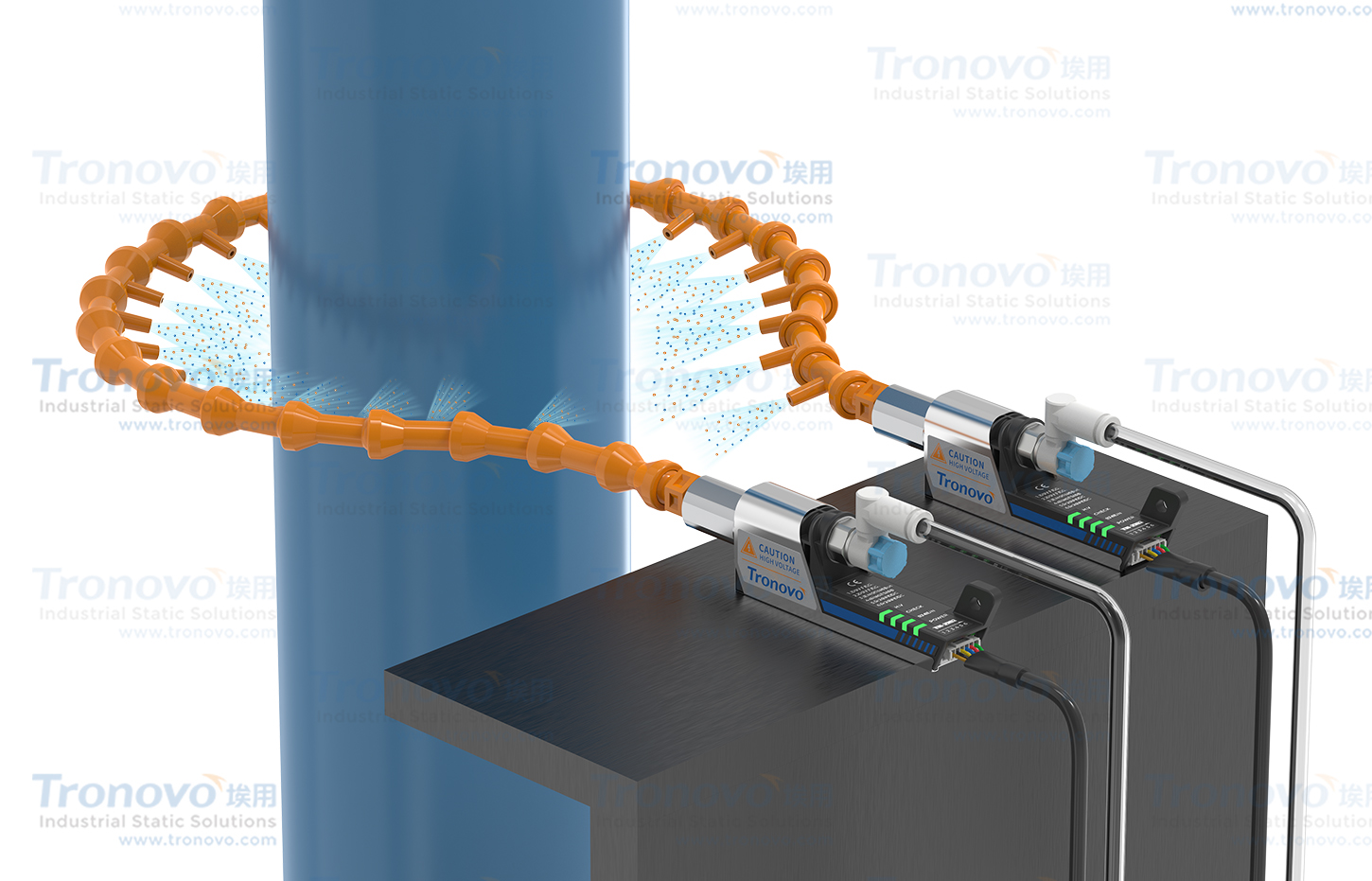

Before the pipe enters the painting line, the surface generates strong static electricity due to friction, which rapidly adsorbs particles in the air of the workshop, and adopts the tip of the ion nozzle to generate a large number of positive and negative ions, which are blown out through the ring-shaped bamboo tube to cover the surface of the pipe.

Core Advantages:

Ring universal nozzle flexible bending, fit the pipe curved surface, no dead angle ion coverage; Ionizer nozzle synergistic dust removal, synchronization to complete the elimination of static electricity and surface cleaning; applicable to different pipe diameters (especially round pipe), static eliminator installation and maintenance is simple;