Background Description:

In the panel manufacturing process, the accumulation of static electricity caused by material friction and equipment operation is the core problem that has plagued production for a long time. Static electricity will strongly absorb the suspended dust in the environment, resulting in the formation of imperceptible contamination on the surface of the panel, which not only affects the cleanliness and flatness of the appearance, but also may cause abnormal line contact or decrease of coating binding force in the subsequent process, which directly leads to an increase in the defective rate of the product, while increasing the frequency of manual wiping and dragging down the overall production line efficiency.

Solution:

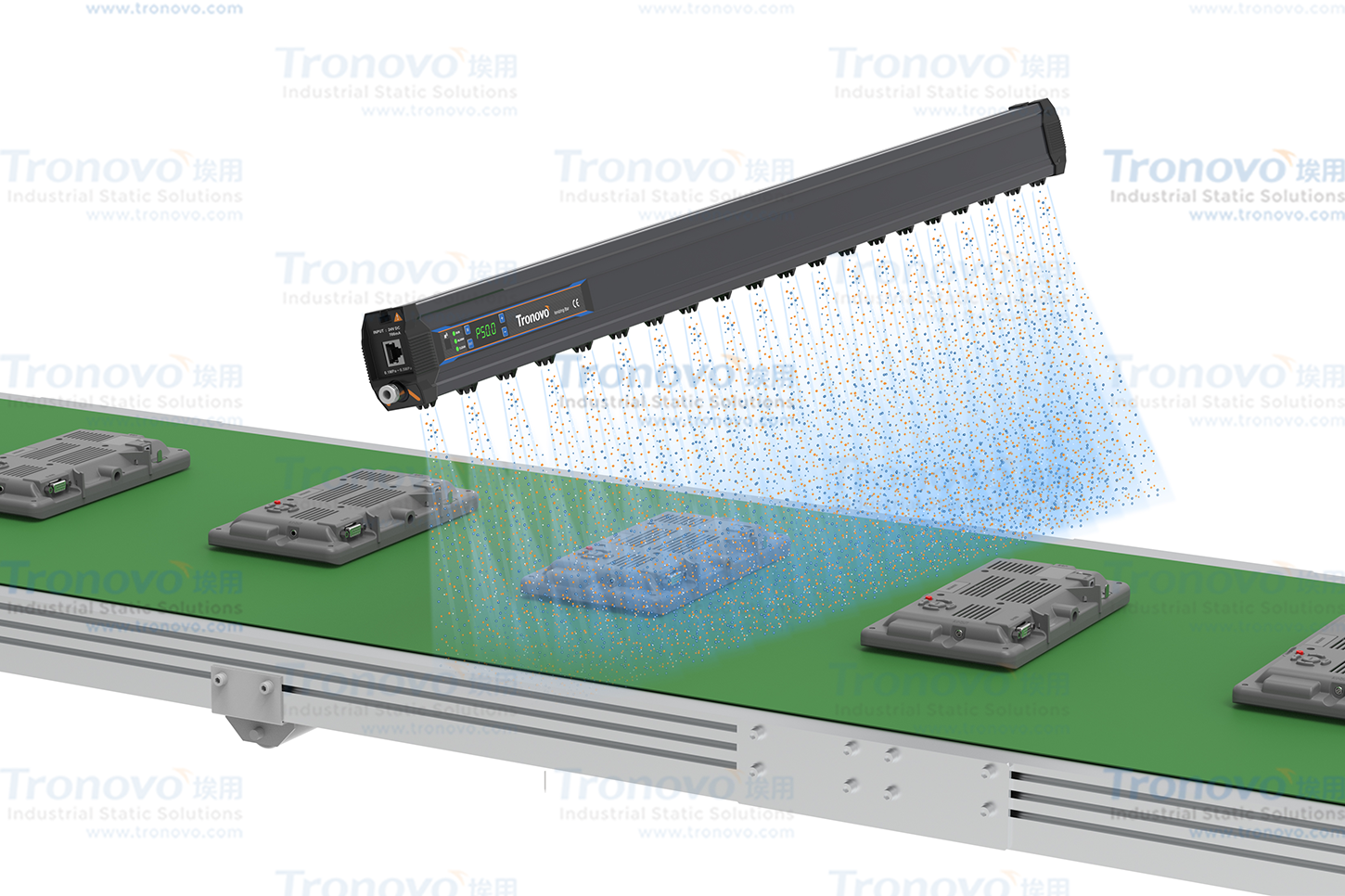

In order to effectively deal with these 1 challenges, the production line has introduced a pulsed AC ionizer bar. According to the characteristics of the panel transmission path and electrostatic generation, the ionizing bar is accurately arranged at the key points above the conveyor belt to ensure that the ion wind fully covers the surface of each panel passing through. When the static elimination rod works, it can continuously and evenly release the positive and negative ion flow, quickly neutralize the electrostatic charge on the surface of the panel, eliminate the electrostatic adsorption force from the root, and make the dust unable to adhere.

Implementation effect:

After the implementation of this 1 scheme, the electrostatic adsorption problem on the surface of the panel has been significantly controlled, the cleanliness has been significantly improved, the quality defects caused by static electricity have been greatly reduced, and the production efficiency and product yield have increased simultaneously.

Next:there is none left