The 21st Shanghai International Tape and Film Exhibition (APFE2025) opened in Shanghai National Convention and Exhibition Center on June 17.

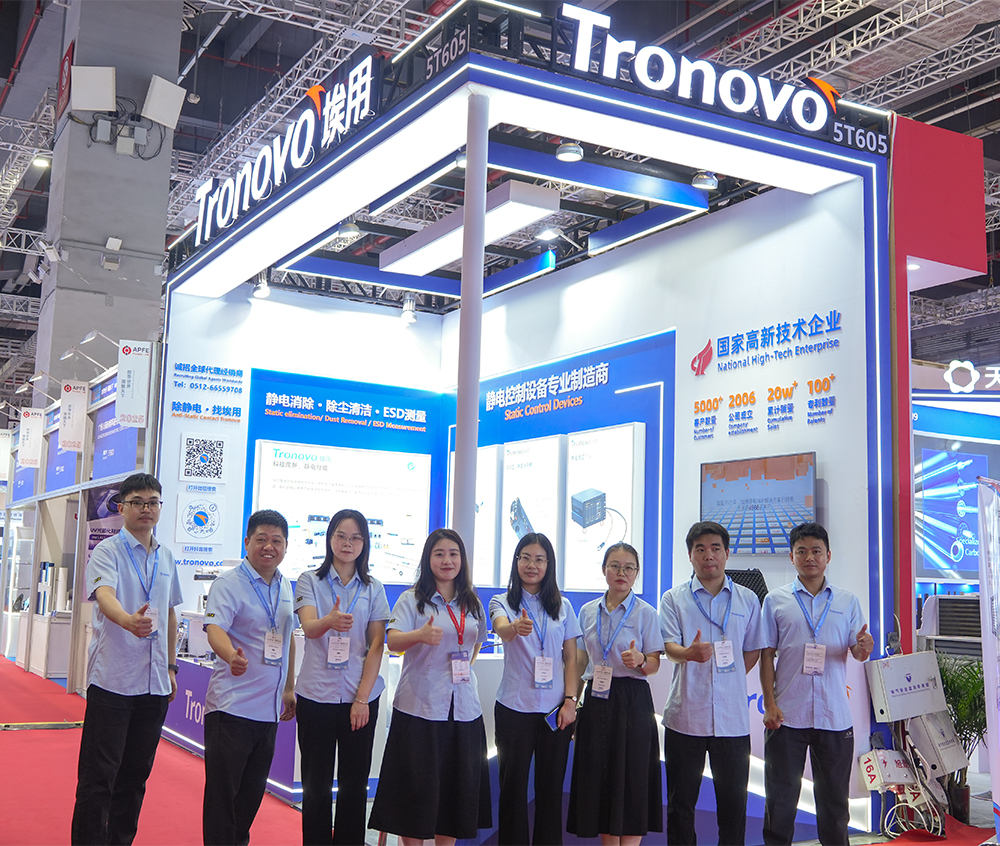

The global leader in electrostatic control technology, Egypt, brought the new product "pulsed DC ion bar" to the exhibition (booth number: 5.1H pavilion -5T605). with cutting-edge electrostatic removal technology, it directly hit the pain points of high-speed production lines, providing efficient and safe electrostatic elimination solutions for film and adhesive tape manufacturing enterprises and helping the intelligent upgrading of the industry.

In the era of high-speed production, electrostatic control is just needed by the industry.

With the rapid development of new energy, electronic display and other fields, the production of film and tape is accelerating towards ultra-thin, high-performance and high-speed. The increase in production line speed has led to increasingly prominent electrostatic problems-material adsorption dust, winding and slipping, discharge damage to products and even fire hazards, seriously restricting yield and production capacity. The industry urgently needs electrostatic control solutions that balance efficiency, stability and safety, especially in high-speed equipment scenarios such as winder and coating line.

Innovative pulse DC technology:

crack the problem of high-speed electrostatic removal

The world's first pulsed DC ion bar is specially designed for high-speed coil production lines and enables intelligent manufacturing through two core technologies:

Millisecond response, 200 percent increase in performance

Using pulse DC technology (Pulse DC Method), breaking through the limitations of traditional AC ion bar. Through the pulse DC ion flow with a specific frequency, the ion balance accuracy within ± 0.1V is realized, and the neutralization efficiency is improved by more than 200 compared with the traditional scheme. Even in the face of a high-speed winding scene of 600 m/min, static electricity can still be eliminated in milliseconds.

No wind mute, suitable for harsh space

The thickness of the fuselage is only 5cm, which can be embedded in the narrow gap of the winding machine, slitting machine and other equipment. The windless design avoids airflow interference with the stability of the material and eliminates noise pollution at the same time. It is especially suitable for clean workshops and precision production lines.

On-site direct attack:

high-speed dynamic demonstration detonates the attention of professional audience.

At the Egyptian instrument booth, the new product was demonstrated in a simulated high-speed winding environment: