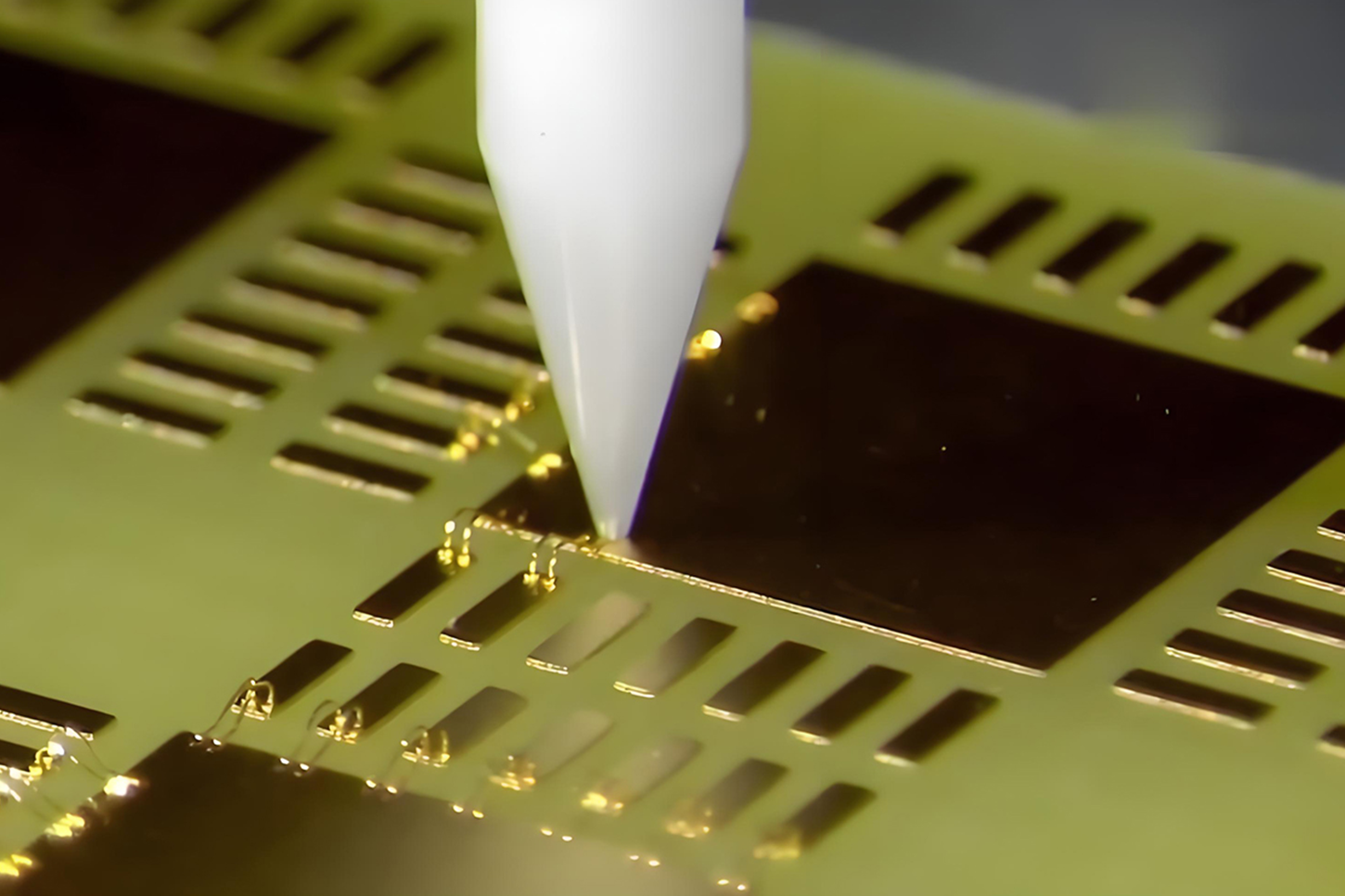

In the wire bonding process of semiconductor chip packaging, windless static eliminators provide a crucial precision static protection solution, directly targeting and solving the core pain point of wire displacement, distortion, or abnormal curvature caused by static electricity.

The root cause of the problem and the limitations of traditional solutions:

In high-speed bonding processes, chips, lead frames, and extremely fine bonding wires (with diameters as thin as 25 μ m) are prone to static electricity accumulation due to high-speed friction and motion. Although traditional blowing static eliminators can neutralize static electricity, the forced airflow generated by them can create new disturbances - weak airflow disturbances can cause the lightweight bonding wire to drift, resulting in positioning deviation of the second solder joint, deformation of the lead curvature, and in severe cases, short circuits or insufficient solder joint tension. Meanwhile, the airflow may carry surrounding particles, contaminating the clean solder pad area. Therefore, in the pursuit of ultra precision and high reliability bonding processes, it is necessary to eliminate static electricity while ensuring zero environmental disturbance.

Targeted solution for windless static eliminators:

1. Zero disturbance precise neutralization

The device generates a balanced ion cloud through a high-voltage electric field, silently neutralizing the static charges on the surfaces of the bonding head, solder pad, lead frame, and bonding wire without generating any airflow. This fundamentally eliminates the paradox of introducing airflow disturbances to solve static electricity.

2. Key area coverage

Rod shaped windless eliminators are usually installed in parallel above the bonding path or on both sides of the substrate transport path to ensure that the bonding area is evenly covered by ions and suppress static electricity generation and accumulation from the source.Protecting the curvature of the bonding wire and the accuracy of the solder joint: After eliminating the electrostatic adsorption force, the bonding wire will not be adsorbed to unexpected positions due to static electricity during the wire bonding process, ensuring the stability of the lead curvature and the accuracy of the second solder joint landing point, significantly reducing the collapse of the wire due to curvature and wire 3 Short circuit risk caused by swaying.

3. Improve yield and overall equipment efficiency

By reducing rework or scrap caused by electrostatic displacement, the packaging yield can be directly improved. Meanwhile, its fanless design eliminates the need for regular cleaning of fan filters and maintenance to prevent ion balance failure caused by dust accumulation, ensuring the continuous and stable operation and output of production equipment.

Next:there is none left