Project Background:

In the automatic production of electronic components, hardware and other precision materials, the vibration plate is the core equipment to achieve efficient and orderly feeding. However, the frequent friction and collision in the vibration process can easily generate static electricity, resulting in the adhesion of materials, the blockage of the feeding channel, the decrease of efficiency, and even the electrostatic damage of components.

Solution:

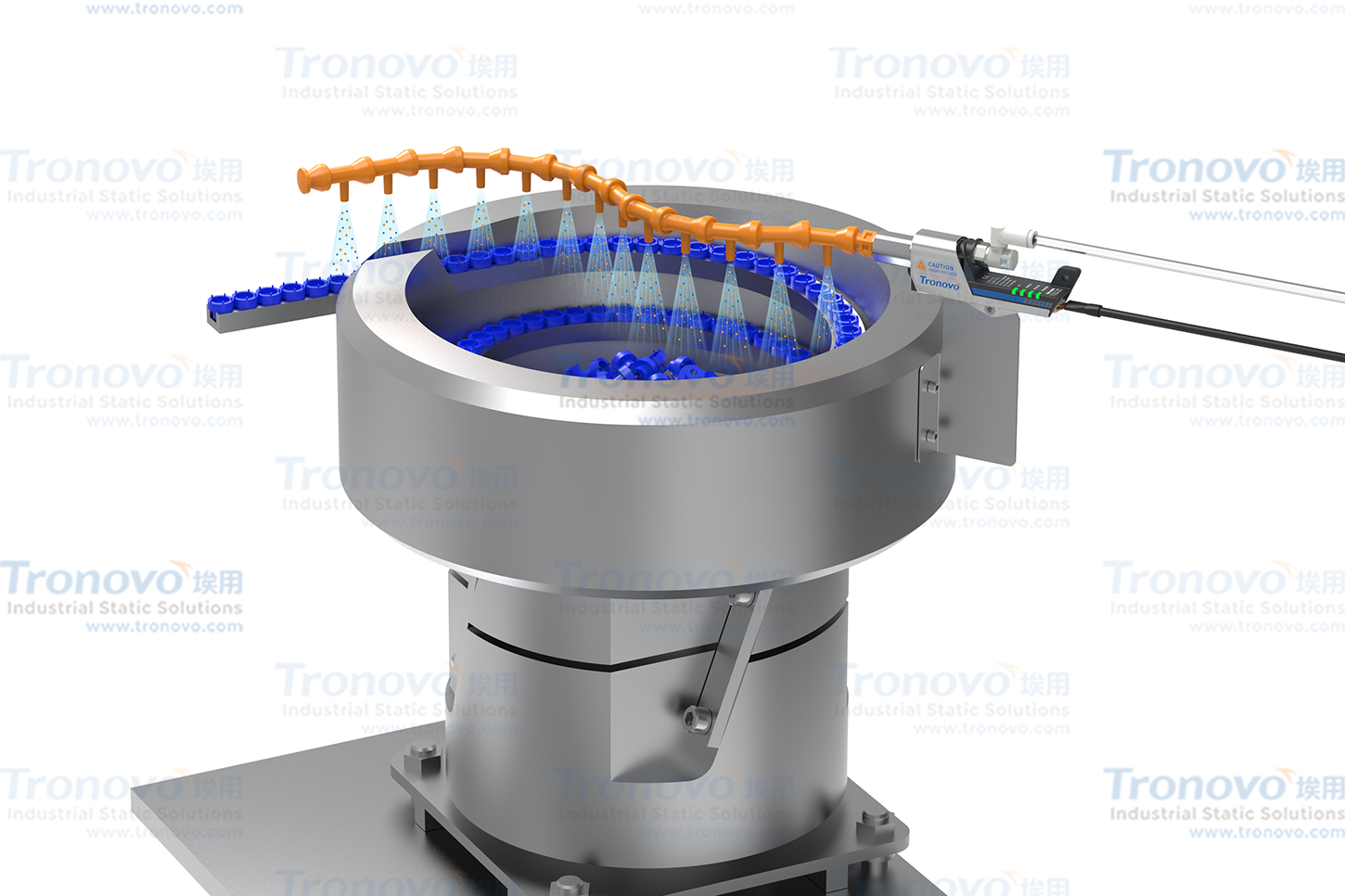

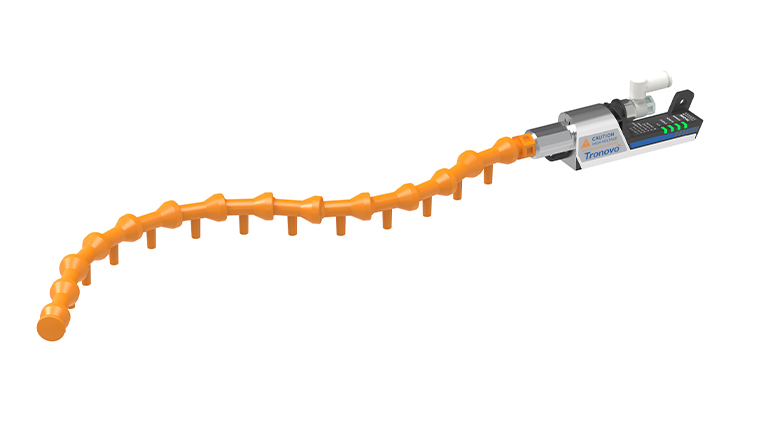

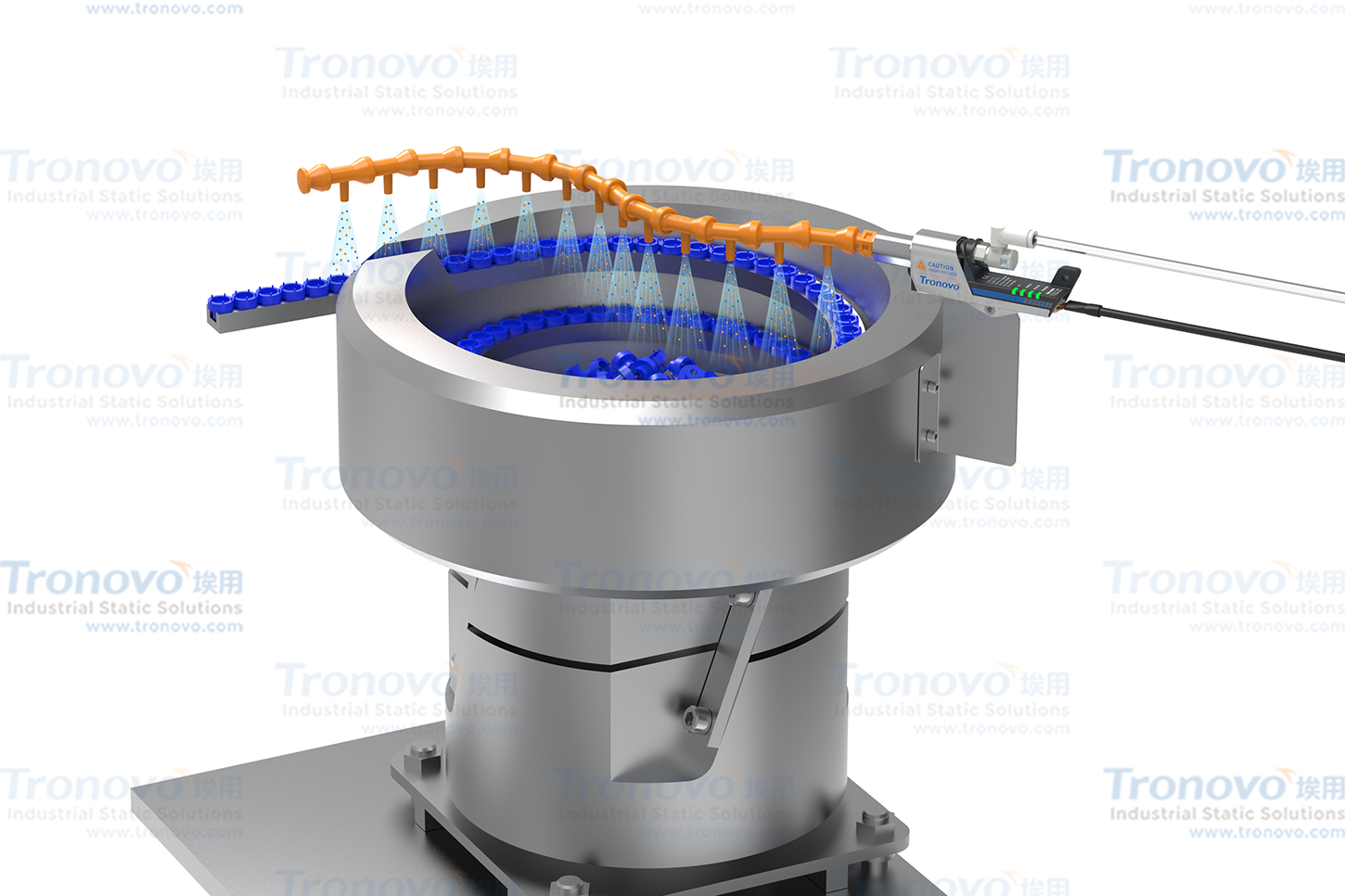

In view of these 1 pain points in the industry, we have introduced a special static elimination scheme for the vibrating disk-by accurately arranging ionizing air nozzles at its internal key positions and discharge ports, and matching flexibly adjustable bamboo tubes, the static eliminator accurately directs the ionizer air supply to the area where static electricity is most concentrated. The ionizer nozzle continuously produces positive and negative ions, efficiently neutralizes the charge, eliminates the accumulation of static electricity from the source, and ensures that the material is always dispersed and smooth during the transmission process.

Core advantages:

This solution has fast response, convenient installation and strong adaptability, and is especially suitable for the production of high-precision components sensitive to static electricity. It not only significantly reduces the downtime and blockage time, improves the overall production efficiency, and more effectively protects the product quality. It is an ideal choice for the vibration disk to remove static electricity.

Next:there is none left